Chevrolet Trax: DTC B0019 OR B0020 (WITH AY0 OR AYF): Passenger instrument panel air bag deployment loop

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptors

DTC B0019 01

Passenger Instrument Panel Air Bag Deployment Loop Stage 1 Short to Battery

DTC B0019 02

Passenger Instrument Panel Air Bag Deployment Loop Stage 1 Short to Ground

DTC B0019 04

Passenger Instrument Panel Air Bag Deployment Loop Stage 1 Open

DTC B0019 0D

Passenger Instrument Panel Air Bag Deployment Loop Stage 1 High Resistance

DTC B0019 0E

Passenger Instrument Panel Air Bag Deployment Loop Stage 1 Low Resistance

DTC B0020 01

Passenger Instrument Panel Air Bag Deployment Loop Stage 2 Short to Battery

DTC B0020 02

Passenger Instrument Panel Air Bag Deployment Loop Stage 2 Short to Ground

DTC B0020 04

Passenger Instrument Panel Air Bag Deployment Loop Stage 2 Open

DTC B0020 0D

Passenger Instrument Panel Air Bag Deployment Loop Stage 2 High Resistance

DTC B0020 0E

Passenger Instrument Panel Air Bag Deployment Loop Stage 2 Low Resistance

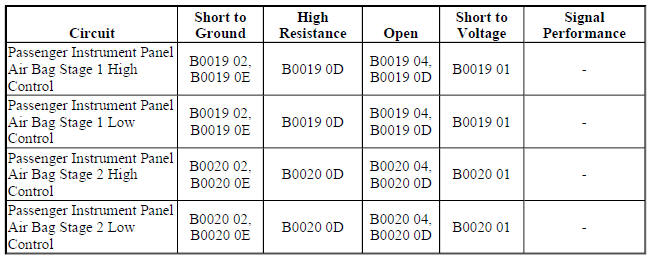

Diagnostic Fault Information

Circuit/System Description

During a side or frontal crash of sufficient force the inflatable restraint sensing and diagnostic module (SDM) will allow current to flow through the deployment loop in order to deploy an air bag or pretensioner. There are 2 shorting bars which will short the control circuits together when the connector is disconnected. This will help to prevent unwanted deployment of the air bag or pretensioner during servicing.

Conditions for Running the DTC

Ignition voltage is between 9-16 V.

Conditions for Setting the DTC

B0019 01, B0020 01

The air bag control circuit is shorted to voltage for 2 seconds.

B0019 02, B0020 02

The air bag control circuit is shorted to ground for 2 seconds.

B0019 04, B0020 04

The air bag control circuit is open for 2 seconds.

B0019 0D, B0020 0D

The air bag deployment loop resistance is greater than 4.2 ohms for 2 seconds.

B0019 0E, B0020 0E

The air bag deployment loop resistance is less than 1.4 ohms for 2 seconds.

Action Taken When the DTC Sets

- The inflatable restraint sensing and diagnostic module requests the instrument cluster to illuminate the AIR BAG indicator.

- The inflatable restraint sensing and diagnostic module will store a DTC, however if an event occurs the system will still attempt deployments.

Conditions for Clearing the DTC

- The condition for setting the DTC no longer exists.

- A history DTC will clear once 100 malfunction-free ignition cycles have occurred.

Diagnostic Aid

NOTE: The following diagnostic aids apply for both current and history DTCs.

An incorrectly installed connector position assurance (CPA) or incorrectly seated connector can cause a shorting bar to short both control circuits together. Check the connectors and CPAs if a DTC with symptom byte 02 or 0E is set, to ensure the shorting bars are not causing the circuits to be shorted together. Shorting bars are used in the locations listed below:

- Passenger instrument panel air bag

- Inline harness connectors

- Harness side of the inflatable restraint sensing and diagnostic module connector

Terminal fretting or incorrectly seated connectors can cause an open/high resistance condition. Check the circuit terminals for fretting or incorrectly seated connector if a DTC with symptom byte 04 or 0D is set.

Reference Information

Schematic Reference

SIR Schematics (Encore), SIR Schematics (Trax)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - TRAX

Description and Operation

Supplemental Inflatable Restraint System Description and Operation

Electrical Information Reference

- Circuit Testing

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

- Connector Repairs

Scan Tool Reference

Control Module References for scan tool information

Special Tools

EL-38125-580 Terminal Release Tool Kit

Circuit/System Verification

NOTE:

- Refer to SIR Service Precautions.

- Inspect all terminals for damage or corrosion when disconnecting connectors. Damage or corrosion in the following requires repair or replacement of the affected component/connector.

- Passenger instrument panel air bag

- inflatable restraint sensing and diagnostic module

- Passenger instrument panel air bag wiring harness connector

- inflatable restraint sensing and diagnostic module wiring harness connector

- The connector and connector position assurance (CPA) may seat independent of each other. Both the connector and CPA should seat with an audible and/or tactile click. The CPA isolates the shorting-bars within the connector allowing the deployment circuit to operate properly.

- If the condition is intermittent or cannot be duplicated, disconnect the connectors and add dielectric grease / lubricant (Nyogel 760G or equivalent, meeting GM specification 9986087). This procedure will correct the high resistance condition due to terminal fretting corrosion.

- Verify the scan tool Deployment Loop Resistance parameters stay consistently between 2.1-4.0 ohms without any spikes or dropouts while moving the harness near each connector listed below:

- F105 Passenger Instrument Panel Air Bag

- Any inline harness connector

- K36 inflatable restraint sensing and diagnostic module

- If less than 2.1 ohms or greater than 4.0 ohms

Refer to Circuit/System Testing.

- If there are spikes or dropouts, perform the following

- Inspect each connector terminal and harness for damage or corrosion and repair as necessary

- Apply dielectric grease / lubricant (Nyogel 760G or equivalent, meeting GM specification 9986087) to each connector terminal

- Insure each connector and CPA is correctly seated.

- If between 2.1-4.0 ohms without any spikes or dropouts

- All OK.

Circuit/System Testing

- Ignition OFF, scan tool disconnected, disconnect the X206 inline harness connector for the F105 Passenger Instrument Panel Air Bag. It may take up to 2 min for all vehicle systems to power down.

- Test for greater than 25 ohms between the appropriate control circuit terminals listed below on the K36 Inflatable Restraint Sensing and Diagnostic Module side of the connector:

- F105 Passenger Instrument Panel Air Bag stage 1 X206 terminal 1 and 2

- F105 Passenger Instrument Panel Air Bag stage 2 X206 terminal 4 and 5

- If 25 ohms or less

- Disconnect the X1 harness connector at the K36 inflatable restraint sensing and diagnostic module.

NOTE: Some connectors may be equipped with shorting bars as a safety component to prevent accidental deployment. When testing on a connector with shorting bars, the shorting bars must be disabled to ensure accurate test results. Insert an appropriate pick from EL- 38125-580 and depress the shorting bars above the appropriate terminals. This will lift the shorting bar from the terminal and allow accurate test results. Take care not to damage the connector, shorting bar, or terminal when depressing the shorting bar.

- Test for infinite resistance between the two control circuits.

- If less than infinite resistance, repair the short between the two circuits.

- If infinite resistance, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If greater than 25 ohms

- Ignition ON.

- Test for less than 11 V between each control circuit terminal listed below on the instrument panel harness side of the connector and ground:

- X206 control circuit terminal 1

- X206 control circuit terminal 2

- X206 control circuit terminal 4

- X206 control circuit terminal 5

- If 11 V or greater

- Ignition OFF, disconnect the X1 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module, ignition ON.

- Test for less than 1 V between each control circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If less than 11 V

- Ignition OFF.

- Test for greater than 25 ohms between each control circuit terminal listed below on the instrument panel harness side of the connector and ground:

- X206 control circuit terminal 1

- X206 control circuit terminal 2

- X206 control circuit terminal 4

- X206 control circuit terminal 5

- If 25 ohms or less

- Disconnect the X1 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module.

- Test for infinite resistance between the control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If greater than 25 ohms

- Install a 3 A fused jumper wire between the control circuit terminals listed below on the instrument panel harness side of the connector:

- F105 Passenger Instrument Panel Air Bag stage 1 X206 terminal 1 and 2

- F105 Passenger Instrument Panel Air Bag stage 2 X206 terminal 4 and 5

- Ignition ON.

- Verify DTC B0017 0E or B0024 0E is set.

- If DTC B0017 0E or B0024 0E is not set

- Ignition OFF, disconnect the X1 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module.

- Test for less than 2 ohms in each control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If DTC B0017 0E or B0024 0E is set

- Ignition OFF, connect the X206 inline harness connector and disconnect the appropriate X1 (DTC B0019) or X2 (DTC B0020) harness connector at the F105 Passenger instrument panel air bag, ignition ON.

- Test for less than 11 V between each control circuit terminals listed below and ground:

- F105 Passenger Instrument Panel Air Bag control circuit terminal 1 X1

- F105 Passenger Instrument Panel Air Bag control circuit terminal 2 X1

- F105 Passenger Instrument Panel Air Bag control circuit terminal 1 X2

- F105 Passenger Instrument Panel Air Bag control circuit terminal 2 X2

- If 11 V or greater

Repair the short to voltage on the circuit.

- If less than 11 V

- Ignition OFF.

- Test for greater than 25 ohms between each control circuit terminals listed below and ground:

- F105 Passenger Instrument Panel Air Bag control circuit terminal 1 X1

- F105 Passenger Instrument Panel Air Bag control circuit terminal 2 X1

- F105 Passenger Instrument Panel Air Bag control circuit terminal 1 X2

- F105 Passenger Instrument Panel Air Bag control circuit terminal 2 X2

- If 25 ohms or less

Repair the short to ground on the circuit.

- If greater than 25 ohms

- Install a 3 A fused jumper wire between the control circuit terminals listed below:

- F105 Passenger Instrument Panel Air Bag stage 1 control circuit terminal 1 X1 and 2 X1

- F105 Passenger Instrument Panel Air Bag stage 2 control circuit terminal 1 X2 and 2 X2

- Ignition ON.

- Verify DTC B0017 0E or B0024 0E is set.

- If DTC B0017 0E or B0024 0E is not set

- Ignition OFF, disconnect the X1 harness connector at the K36 Inflatable Restraint Sensing and Diagnostic Module.

- Test for less than 2 ohms in each control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit between the F105 Passenger Instrument Panel Air Bag connector and the X206 inline harness connector.

- If less than 2 ohms, replace the K36 Inflatable Restraint Sensing and Diagnostic Module.

- If less than 2 ohms

- Ignition OFF, connect the harness connector at the F105 Passenger Instrument Panel Air Bag, press in the CPA (if equipped) until an audible and/or tactile click is heard.

- Ignition ON, clear DTCs. Operate the vehicle within the Conditions for Running the DTC.

- Verify DTC B0019 or B0020 is not set.

- If DTC B0019 or B0020 is set

Test or replace the F105 Passenger Instrument Panel Air Bag.

- If DTC B0019 or B0020 is not set

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Airbag Instrument Panel Module Replacement

- SIR/SRS Wiring Repairs

- Control Module References for inflatable restraint sensing and diagnostic module control module replacement, programming and setup