Chevrolet Trax: Noise and vibration analysis

A noise or vibration that is noticeable when the vehicle is in motion MAY NOT be the result of the transmission.

If noise or vibration is noticeable in PARK and NEUTRAL with the engine at idle, but is less noticeable as RPM increases, the vibration may be a result of poor engine performance.

- Vibration may also be caused by a small amount of water inside the converter.

- Inspect the engine and transmission mounts for damage and loose bolts.

- Inspect the transmission case mounting holes for the following conditions:

- Missing bolts, nuts, and studs

- Stripped threads

- Cracks

- Inspect the flywheel for the following conditions:

- Missing or loose bolts

- Cracks

- Imbalance

- Inspect the torque converter for the following conditions:

- Missing or loose bolts or lugs

- Missing or loose balance weights

- Imbalance caused by heat distortion or fluid contamination

- If the noise or vibration is noticeable in PARK and NEUTRAL with the

engine at idle, but is more

noticeable as RPM increases, the vibration may be an engine imbalance or a

transmission imbalance.

Refer to Torque Converter Diagnosis.

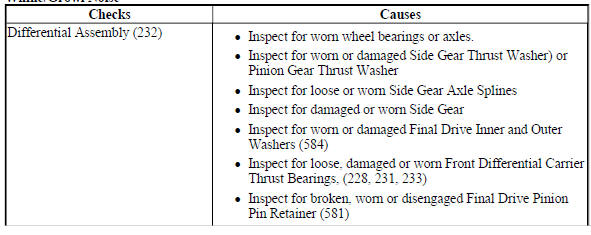

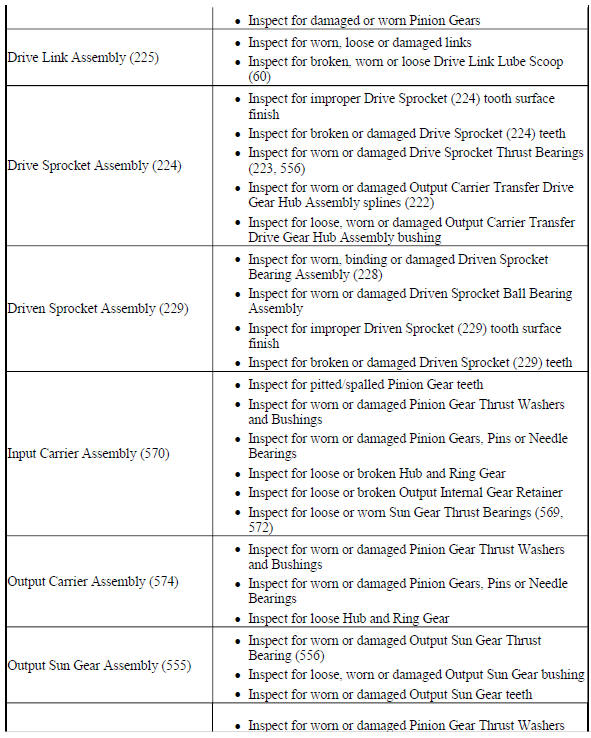

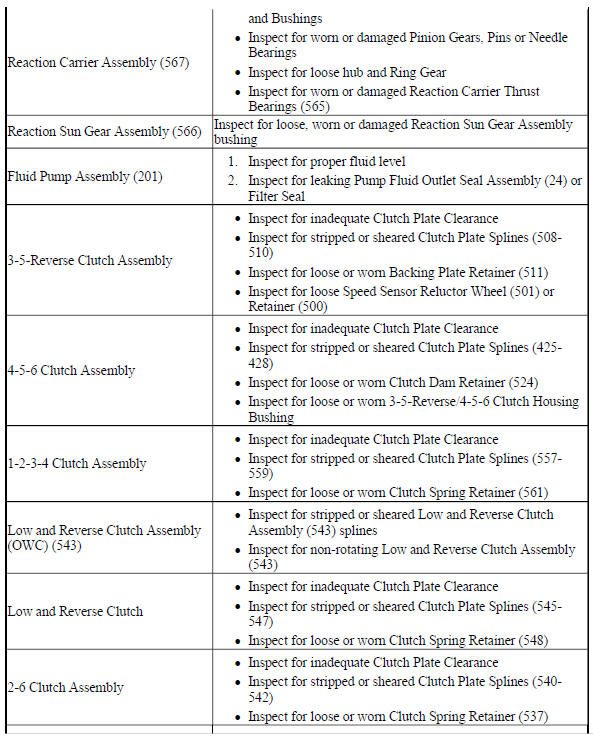

WHINE/GROWL NOISE

Whine/Growl Noise

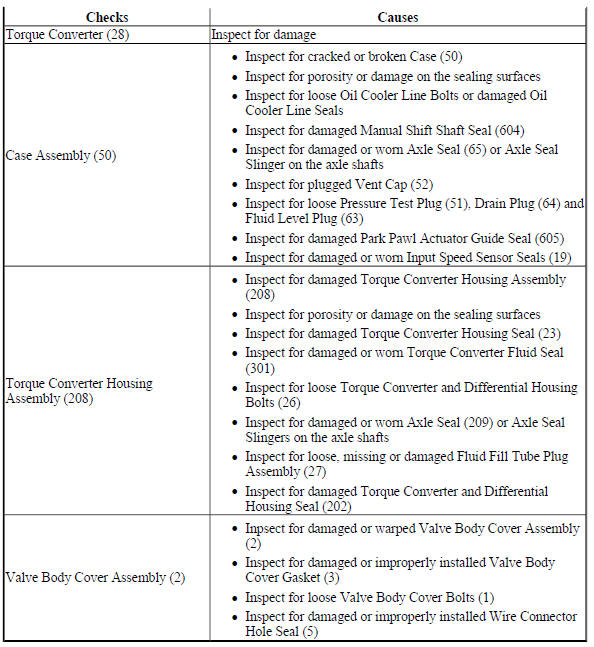

AUTOMATIC TRANSMISSION FLUID LEAKS

Automatic Transmission Fluid Leaks

SHIFT INDICATOR INDICATES WRONG GEAR SELECTION

Shift Indicator Indicates Wrong Gear Selection

.jpg)

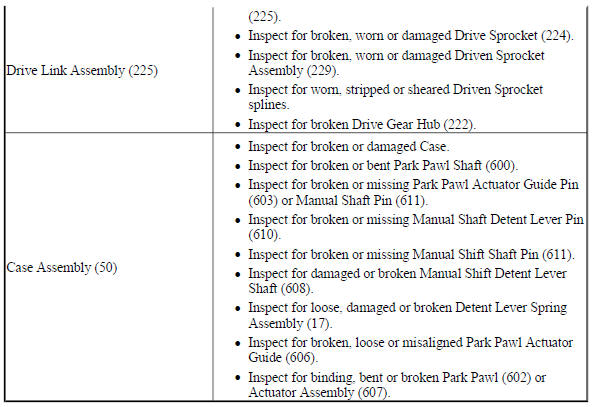

NO PARK

No Park

.jpg)

HARSH GARAGE SHIFT

Harsh Garage Shift

.jpg)

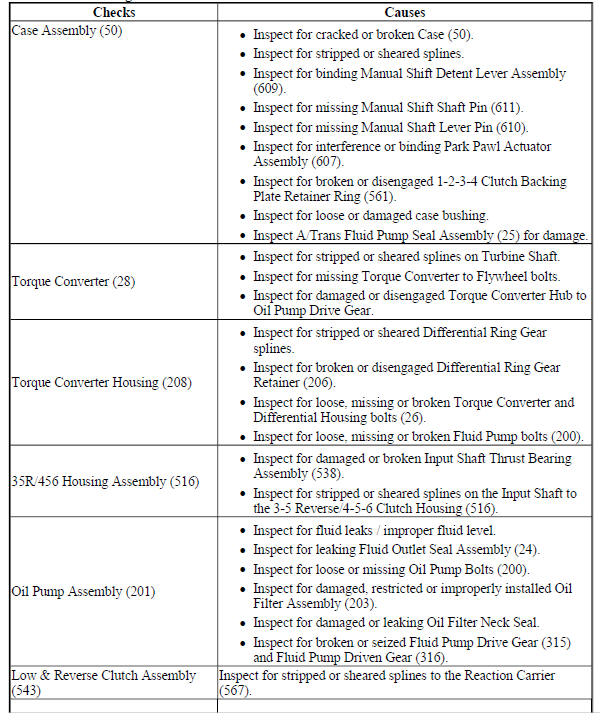

NO DRIVE IN ALL RANGES

No Drive in All Ranges

.jpg)

NO FIRST AND REVERSE GEARS

No First and Reverse Gears

.jpg)

NO FIRST, SECOND, THIRD, AND FOURTH GEAR

No First, Second, Third, and Fourth Gear

.jpg)

.jpg)

NO SECOND AND SIXTH GEAR

No Second and Sixth Gear

.jpg)

HARSH OR LATE FIRST, SECOND, THIRD, AND FOURTH SHIFT

Harsh or Late First, Second, Third, and Fourth Shift

.jpg)

.jpg)

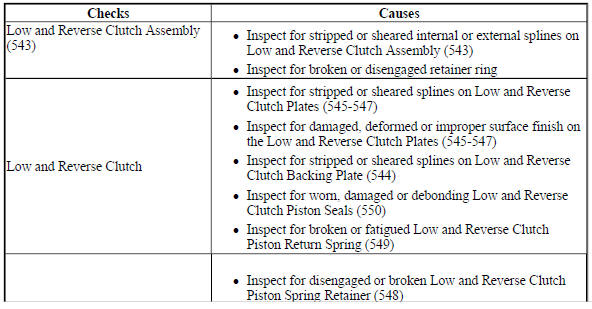

HARSH FIRST AND REVERSE SHIFT

Harsh First and Reverse Shift

.jpg)

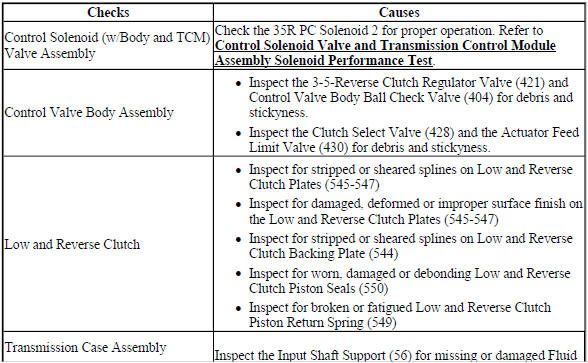

NO THIRD, FIFTH, AND REVERSE GEAR

No Third, Fifth, and Reverse Gea

.jpg)

.jpg)

HARSH OR LATE SECOND AND SIXTH SHIFT

Harsh or Late Second and Sixth Shift

.jpg)

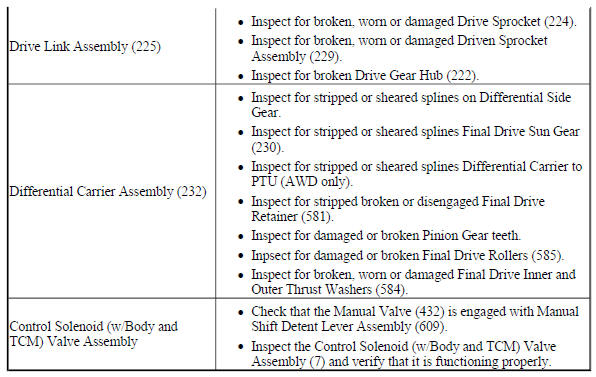

NO FOURTH, FIFTH, AND SIXTH GEAR

No Fourth, Fifth, and Sixth Gear

.jpg)

HARSH OR LATE THIRD, FIFTH, AND REVERSE SHIFT

Harsh or Late Third, Fifth, and Reverse Shift

.jpg)

HARSH FOURTH, FIFTH, AND SIXTH SHIFT

Harsh Fourth, Fifth, and Sixth Shift

.jpg)

NO TORQUE CONVERTER CLUTCH APPLY

No Torque Converter Clutch Apply

.jpg)

NO TORQUE CONVERTER CLUTCH RELEASE

No Torque Converter Clutch Release

.jpg)

HARSH TORQUE CONVERTER CLUTCH APPLY, OR INOPERATIVE OR NO ELECTRONICALLY CONTROLLED CAPACITY CLUTCH CONTROL

Harsh Torque Converter Clutch Apply, or Inoperative or No Electronically Controlled Capacity Clutch Control

.jpg)

NO REVERSE GEAR

No Reverse Gear

.jpg)

FLUID PRESSURE HIGH OR LOW

Fluid Pressure High or Low

.jpg)

.jpg)