Chevrolet Trax: DTC P0030-P0032, P0036-P0038, P0053, P0054, P0135, OR P0141

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provide an overview of each diagnostic category.

DTC Descriptors

DTC P0030

HO2S Heater Control Circuit Sensor 1

DTC P0031

HO2S Heater Control Circuit Low Voltage Sensor 1

DTC P0032

HO2S Heater Control Circuit High Voltage Sensor 1

DTC P0036

HO2S Heater Control Circuit Sensor 2

DTC P0037

HO2S Heater Control Circuit Low Voltage Sensor 2

DTC P0038

HO2S Heater Control Circuit High Voltage Sensor 2

DTC P0053

HO2S Heater Resistance Sensor 1

DTC P0054

HO2S Heater Resistance Sensor 2

DTC P0135

HO2S Heater Performance Sensor 1

DTC P0141

HO2S Heater Performance Sensor 2

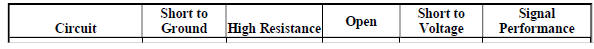

Diagnostic Fault Information

.jpg)

Typical Scan Tool Data

HO2S Sensor 1 Current/HO2S Sensor 2 Current

.jpg)

Circuit/System Description

Heated oxygen sensors (HO2S) are used for fuel control and post-catalyst monitoring. Each HO2S compares the oxygen content of the surrounding air with the oxygen content in the exhaust stream. Each HO2S must reach operating temperature to provide an accurate voltage signal. A heating element inside each of the HO2S minimizes the time required for the sensor to reach operating temperature. Voltage is provided to the heater by an ignition voltage circuit through a fuse. With the engine running, ground is provided to the heater by the HO2S heater low control circuit, through a low side driver within the engine control module (ECM). The ECM uses pulse-width modulation (PWM) to control the HO2S heater operation to maintain a specific HO2S operating temperature range.

Conditions for Running the DTC

P0030, P0031, P0032, P0036, P0037 and P0038

- The system voltage is between 11-32 V.

- The engine speed is greater than 400 RPM.

- The DTCs run continuously when the above conditions are met for greater than 5 s.

P0053 and P0054

- DTCs P0111, P0112, P0113, P0114, P0116, P0117, P0118, P0119 or P2610 are not set.

- The system voltage is less than 32 V.

- The ignition is OFF for greater than 8 h.

- The engine is running.

- The ECT is between -30 to +45ºC (-22 to +113ºF).

- The engine coolant temperature (ECT) and the intake air temperature (IAT) are within 8ºC (14ºF).

- The DTCs run once per valid cold start-up when the above conditions are met

P0135 and P0141

- DTCs P0116, P0117, P0118, P0119 or P0128 are not set.

- The system voltage is between 10-32 V.

- The HO2S heaters are at operating temperature.

- The scan tool HO2S Heater device control is not active.

- The commanded HO2S heater duty cycle is greater than 0%.

- The DTCs run twice per drive cycle when the above conditions are met for greater than 30 s.

Conditions for Setting the DTC

P0030, P0031, P0032, P0036, P0037 and P0038

The ECM detects that the commanded state of the driver and the actual state of the control circuit do not match for greater than 5 s.

P0053 and P0054

The ECM detects the HO2S heater is not within 7.5-13 ohms at engine start-up.

P0135 and P0141

The ECM detects the HO2S heater current is less than 0.30 A or greater than 2.5 A for greater than 8 s.

Action Taken When the DTC Sets

DTC P0030, P0031, P0032, P0036, P0037, P0038, P0053, P0054, P0135, and P0141 are Type B DTCs.

Conditions for Clearing the DTC

DTC P0030, P0031, P0032, P0036, P0037, P0038, P0053, P0054, P0135, and P0141 are Type B DTCs.

Diagnostic Aids

- If the condition is intermittent, move the related harnesses and connectors, with the engine operating, while monitoring the scan tool circuit status parameters for the component. The circuit status parameters will change from OK or Not Run to Malfunction if there is a condition with the circuit or a connection.

- An open fuse in the HO2S heater circuit may be caused by the heater element in one of the sensors. The condition may not be present until the sensor operates for a period of time. If no fault is present in the heater circuit, monitor the amperage of each heater with a scan tool to determine if one of the heater elements is the cause of the open fuse. Inspect the sensor pigtail or the harness for contacting the exhaust system.

Reference Information

Schematic Reference

Engine Controls Schematics (Encore) , Engine Controls Schematics (Trax)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - TRAX

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

DTC Type Reference

Powertrain Diagnostic Trouble Code (DTC) Type Definitions (LUV) , Powertrain Diagnostic Trouble Code (DTC) Type Definitions (2H0)

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Engine idling.

- Verify the parameters listed below do not display Malfunction.

- HO2S 1 or 2 Heater Control Circuit Low Voltage Test Status

- HO2S 1 or 2 Heater Control Circuit Open Test Status

- HO2S 1 or 2 Heater Control Circuit High Voltage Test Status

- If Malfunction is displayed

Refer to Circuit/System Testing.

- If Malfunction is not displayed

- Operate the vehicle within the conditions for running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

- Verify the DTC does not set.

- If the DTC sets

Refer to Circuit/System Testing.

- If the DTC does not set

- All OK.

Circuit/System Testing

- Ignition OFF, disconnect the harness connector at the appropriate B52 Heated Oxygen Sensor. Ignition ON.

- Verify that a test lamp illuminates between the ignition voltage circuit terminal 1 and ground.

- If the test lamp does not illuminate and the circuit fuse is good

- Ignition OFF.

- Test for less than 2 ohms in the ignition circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, verify the fuse is OK and there is voltage at the fuse.

If the test lamp does not illuminate and the circuit fuse is open

- Ignition OFF, remove the test lamp.

- Test for infinite resistance between the ignition circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, test all components connected to the fuse and replace as necessary.

- If the test lamp illuminates

- Verify that a test lamp does not illuminate between the ignition voltage circuit terminal 1 and the control circuit terminal 2.

- If the test lamp illuminates

- Ignition OFF, remove the test lamp, disconnect the harness connector at the K20 Engine Control Module.

- Test for infinite resistance between the control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance, replace the K20 Engine Control Module.

- If the test lamp does not illuminate

- Remove the test lamp.

- Verify the scan tool HO2S 1 or 2 Heater Control Circuit High Voltage Test Status parameter is OK when commanding the HO2S Heater Sensor 1 or 2 ON with a scan tool.

- If OK is not displayed

- Ignition OFF, disconnect the harness connector at the K20 Engine Control Module, ignition ON.

- Test for less than 1 V between the control circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the K20 Engine Control Module.

- If OK is displayed

NOTE:

- Less than 10 ohms of additional resistance on the ignition voltage circuit, or control circuit may set a DTC. If there is a resistance on a circuit, the driver will remain ON and the scan tool HO2S High Voltage Test Status parameter will display OK.

- Performing this test may set additional DTCs.

- Install a 10 A fused jumper wire between the control circuit terminal 2 and the ignition voltage circuit terminal 1.

NOTE: This test may only be performed once per key cycle. If test is repeated, ignition OFF, allow the engine control module to shut down completely, then ignition ON.

- Verify the scan tool HO2S 1 or 2 Heater Control Circuit High Voltage Test Status parameter is Malfunction when commanding the HO2S Heater Sensor 1 or 2 ON with a scan tool.

- If Malfunction is not displayed

- Ignition OFF, remove the jumper wire, disconnect the harness connector at the K20 Engine Control Module.

- Test for less than 2 ohms in the control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K20 Engine Control Module.

- If Malfunction is displayed

- Test or replace the B52 Heated Oxygen Sensor.

Component Testing

- Ignition OFF, disconnect the harness connector at the appropriate B52 Heated Oxygen Sensor.

- Test for 8-20 ohms between the ignition voltage circuit terminal 1 and the control circuit terminal 2.

- If not within the specified range

Replace the B52 Heated Oxygen Sensor.

- If within the specified range

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Heated Oxygen Sensor Replacement - Sensor 1

- Heated Oxygen Sensor Replacement - Sensor 2

- Perform the scan tool Heated Oxygen Sensor Resistance Learn Reset after replacing a HO2S.

- Control Module References for ECM replacement, programming and setup.