Chevrolet Trax: DTC B3811: Rear washer relay

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category

DTC Descriptor

DTC B3811

Rear Washer Relay Circuit

For symptom byte information, refer to Symptom Byte List .

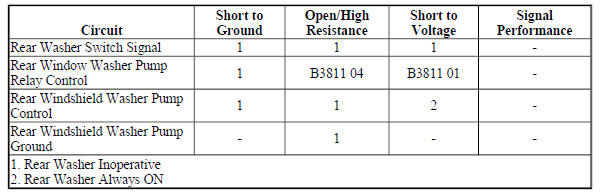

Diagnostic Fault Information

Circuit/System Description

The body control module (BCM) controls the rear washer based on an input from the rear wiper switch, which is part of the windshield wiper/washer switch. The BCM monitors the windshield wiper/washer switch through two separate signal circuits and a low reference circuit. The rear wiper switch uses a resistor ladder to determine low speed, intermittent, and rear washer operation. The BCM monitors applies and monitors voltage on the rear wiper switch signal circuit. When the rear wiper switch is placed in the low speed, intermittent, or rear washer position, the voltage is pulled down through a different resistor in the resistor ladder, reducing the voltage seen at the BCM. The BCM will respond by commanding the specific rear wiper function.

The windshield washer uses a single windshield washer pump to provide fluid for both the front and rear washers. Changing the polarity of the motor will cause it to spin in opposite directions, feeding fluid to the front or rear. When rear washers are requested, the BCM applies voltage to the rear window washer pump relay control circuit. This causes the contacts in the rear washer pump relay to close and supplies voltage to the windshield washer pump. Ground for the windshield washer pump is provided through the windshield washer pump relay, which is switched to ground in it's at-rest state.

Conditions for Running the DTC

- Ignition ON

- The system voltage is between 9-16 V

Conditions for Setting the DTC

B3811 01

A short to voltage has been detected on the rear window washer pump relay control circuit

B3811 04

A open/high resistance has been detected on the rear window washer pump relay control circuit

Action Taken When the DTC Sets

Rear washer operation is disabled.

Conditions for Clearing the DTC

- A current DTC clears when the diagnostic runs and passes.

- A history DTC will clear after 50 consecutive ignition cycles without a fault present.

Diagnostic Aids

The rear liftgate must be closed in order for the rear wiper to work

Reference Information

Schematic Reference

Wiper/Washer Schematics (Encore), Wiper/Washer Schematics (Trax)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - TRAX

Description and Operation

Wiper/Washer System Description and Operation

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

- Ignition ON.

- Verify the Scan Tool Rear Closure Ajar Switch Parameter changes between Inactive and Active when Opening and closing the liftgate.

If the parameter does not change

Refer to Door Ajar Indicator Malfunction

If the parameter changes

- Verify the scan tool Rear Wiper Switch parameter changes between On and Off when cycling the rear wiper switch ON and OFF.

If the parameter does not change

Refer to Rear Wiper System Malfunction

If the parameter changes

- Verify the G24 Windshield Washer Pump turns on and off when commanding the rear washers OFF and ON with the rear washer switch

If the Rear Window Washers do not turn ON

Refer to Circuit/System Testing

If the Rear Window Washers turn ON

- All OK.

Circuit/System Testing

- Ignition OFF, and all vehicle systems OFF. Disconnect the X2 harness connector at the X50A Fuse Block - Underhood. It may take up to 2 min for all vehicle systems to power down.

- Test for less than 10 ohms between the ground circuit terminal C5 and ground:

If 10 ohms or greater

- Test for less than 2 ohms in the ground circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, repair the open/high resistance in the ground connection.

If less than 10 ohms

- Connect the X2 harness connector and disconnect the X1 harness connector at the X50A Fuse Block - Underhood.

- Test for infinite resistance between each of the control circuit terminals listed below and ground.

- Terminal G3

- Terminal H3

If less than Infinite resistance

Repair the short to ground on the circuit.

If infinite resistance

- Connect the X1 harness connector at the X50A Fuse Block - Underhood. Disconnect the harness connector at the G24 Windshield Washer Pump, ignition ON.

- Test for less than 1 V between the control circuit terminals listed below and ground:

- Terminal 1

- Terminal 2

If 1 V or greater

- Ignition OFF, disconnect the X1 harness connector at the X50A Fuse Block - Underhood.

- Test for less than 1 V between the control circuit and ground.

- If 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, test or replace the X50A Fuse Block - Underhood.

If less than 1 V

- Ignition OFF, and all vehicle systems OFF. It may take up to 2 min for all vehicle systems to power down.

- Test for less than 10 ohms between the control circuit terminal 1 and ground.

If 10 ohms or greater

- Ignition OFF, disconnect the X1 harness connectors at the X50A Fuse Block - Underhood.

- Test for less than 2 ohms in the control circuit end to end:

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the X50A Fuse Block - Underhood.

If less than 10 ohms

- Test for less than 10 ohms between the control circuit terminal 2 and ground.

If 10 ohms or greater

- Ignition OFF, disconnect the X1 harness connectors at the X50A Fuse Block - Underhood.

- Test for less than 2 ohms in the control circuit end to end:

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the X50A Fuse Block - Underhood.

If less than 10 ohms

- Connect a test lamp between the control circuit terminal 1 and the control circuit terminal 2, ignition ON.

- Verify the test lamp does NOT turn ON and OFF when commanding the rear washer ON and OFF with the rear washer switch.

If the test lamp turns ON and OFF

Test or replace the G24 Windshield Washer Pump.

If the test lamp does not turn ON and OFF

- Ignition OFF, connect the harness connector at the G24 Windshield Washer Pump. Disconnect the X2 harness connector at the X50A Fuse Block - Underhood, ignition ON.

- Connect a test lamp between the control circuit terminal G2 and ground.

- Verify the test lamp turns ON and OFF when commanding the rear washer ON and OFF with the rear washer switch.

If the test lamp is always OFF

- Ignition OFF, remove the test lamp. Disconnect the X1 harness connector at the K9 Body Control Module.

- Test for infinite resistance between the control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance.

- Test for less than 2 ohms in the control circuit end to end.

- If 2 ohms or greater, repair the short to ground on the circuit.

- If less than 2 ohms, replace the K9 Body Control Module

If the test lamp is always ON

- Ignition OFF, remove the test lamp. Disconnect the X1 harness connector at the K9 Body Control Module, ignition ON.

- Test for less than 1 V between the control circuit and ground.

- If 2 ohms or greater, repair the short to voltage on the circuit.

- If less than 2 ohms, replace the K9 Body Control Module

If the test lamp turns ON and OFF.

- Test or replace the X50A Fuse Block - Underhood.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Windshield Washer Pump Replacement

- Front Compartment Fuse Block Replacement

- Windshield Wiper and Washer Switch Replacement (Encore), Windshield Wiper and Washer Switch Replacement (Trax)

- Control Module References for body control module replacement, programming, and setup.