Chevrolet Trax: Cleanliness and care

An automobile engine is a combination of many of the following surfaces:

- Machined

- Honed

- Polished

- Lapped

The tolerances of these surfaces are measured in the ten-thousandths of an inch. When you service any internal engine part, cleanliness and care are important. Apply a liberal coating of engine oil to the friction areas during assembly in order to protect and lubricate the surfaces on initial operation. Throughout this section, practice proper cleaning and protection procedures to the machined surfaces and to the friction areas.

Whenever you remove the valve train components, keep the components in order. Follow this procedure in order to install the components in the same locations and with the same mating surfaces as when removed.

WARNING: Refer to Battery Disconnect Warning .

Disconnect the negative battery cables before you perform any major work on the engine.

USE OF ROOM TEMPERATURE VULCANIZING (RTV) AND ANAEROBIC SEALANT

Pipe Joint Compound

NOTE: Three types of sealer are commonly used in engines. These are RTV sealer, anaerobic gasket eliminator sealer, and pipe joint compound. The correct sealer and amount must be used in the proper location to prevent oil leaks. DO NOT interchange the 3 types of sealers. Use only the specific sealer or the equivalent as recommended in the service procedure.

- Pipe joint compound is a pliable sealer that does not completely harden. This type sealer is used where 2 non-rigid parts, such as the oil pan and the engine block, are assembled together.

- Do not use pipe joint compound in areas where extreme temperatures are expected. These areas include: exhaust manifold, head gasket, or other surfaces where gasket eliminator is specified.

- Follow all safety recommendations and directions that are on the container. To remove the sealant or the gasket material.

- Apply the pipe joint compound to a clean surface. Use a bead size or quantity as specified in the procedure. Run the bead to the inside of any bolt holes. Do not allow the sealer to enter any blind threaded holes, as it may prevent the bolt from clamping properly.

- Apply a continuous bead of pipe joint compound to one sealing surface. Sealing surfaces to be resealed must be clean and dry.

- Tighten the bolts to specifications. Do not overtighten.

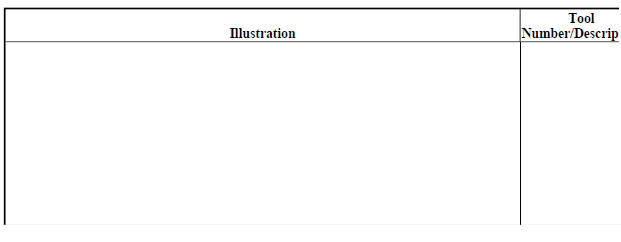

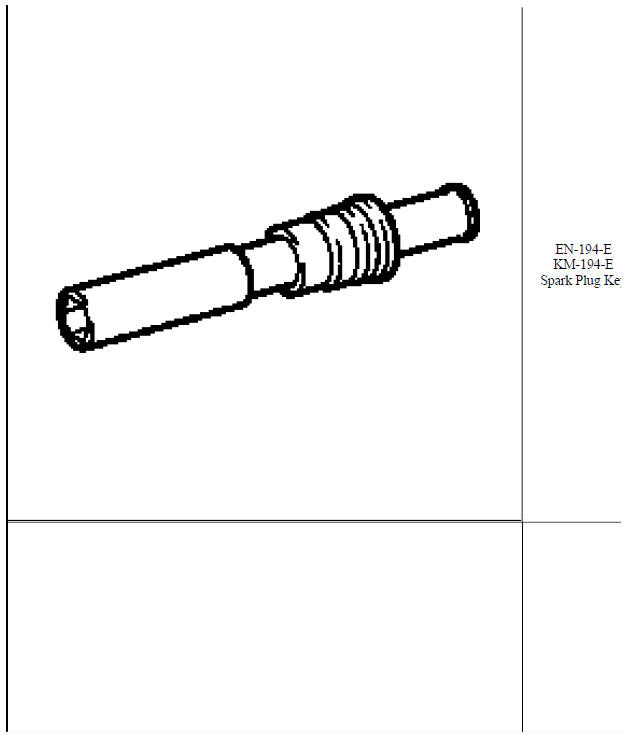

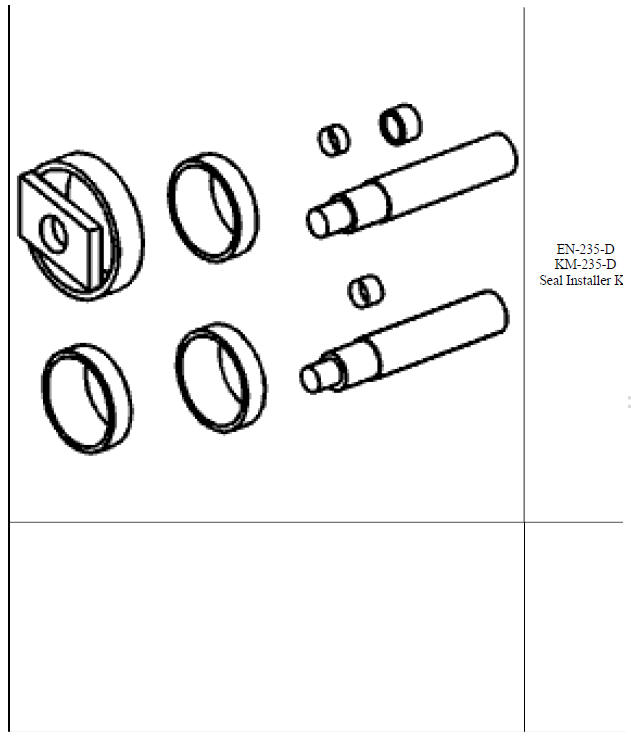

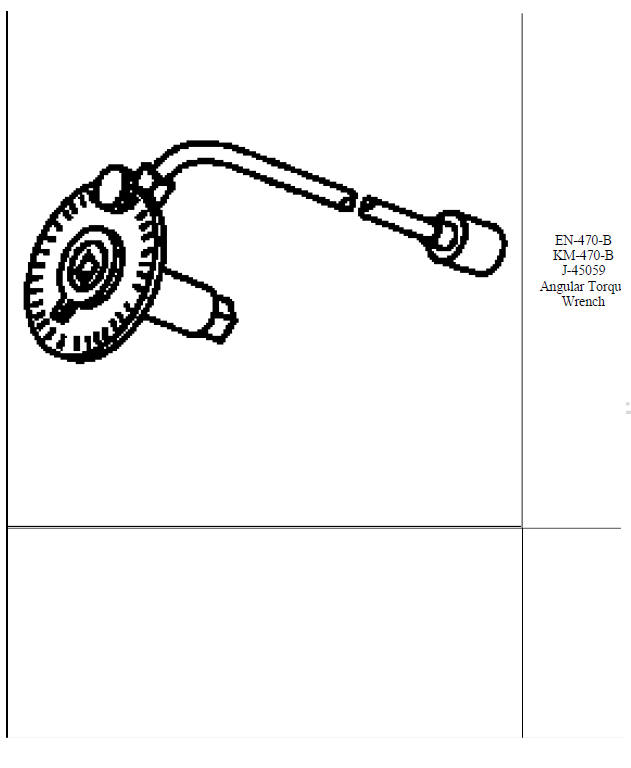

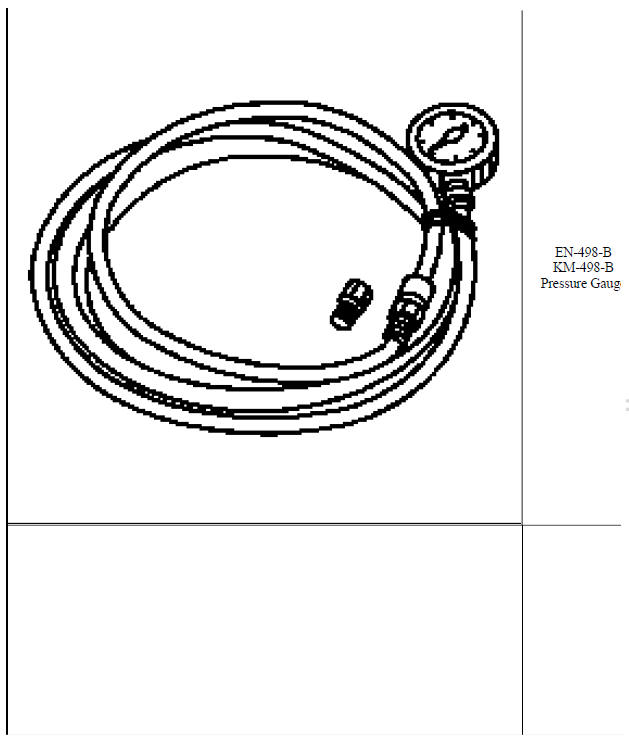

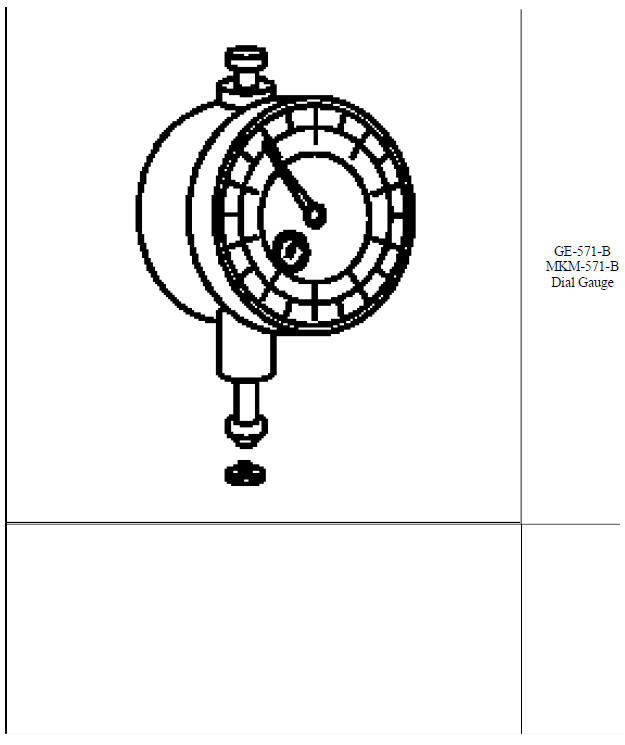

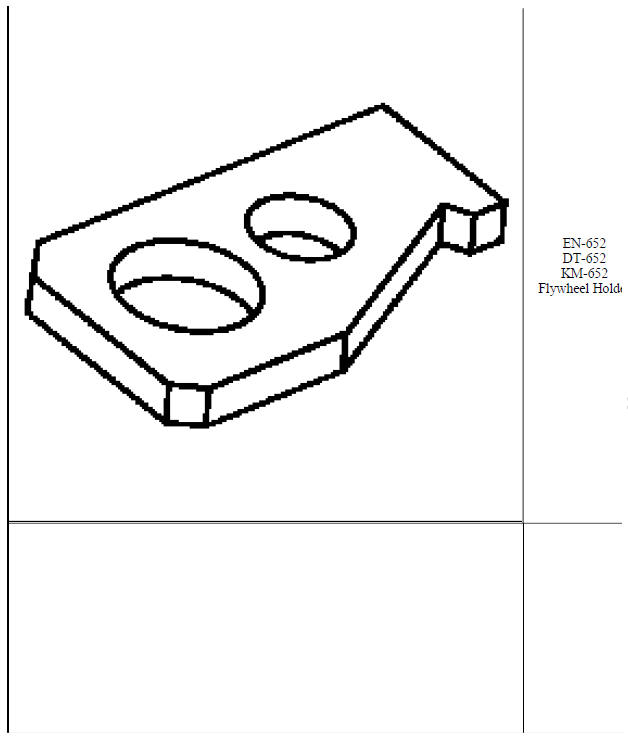

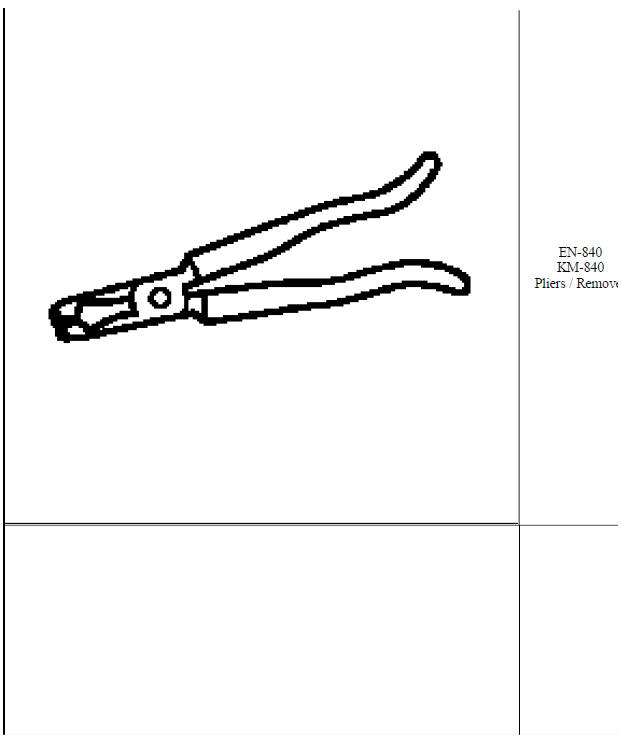

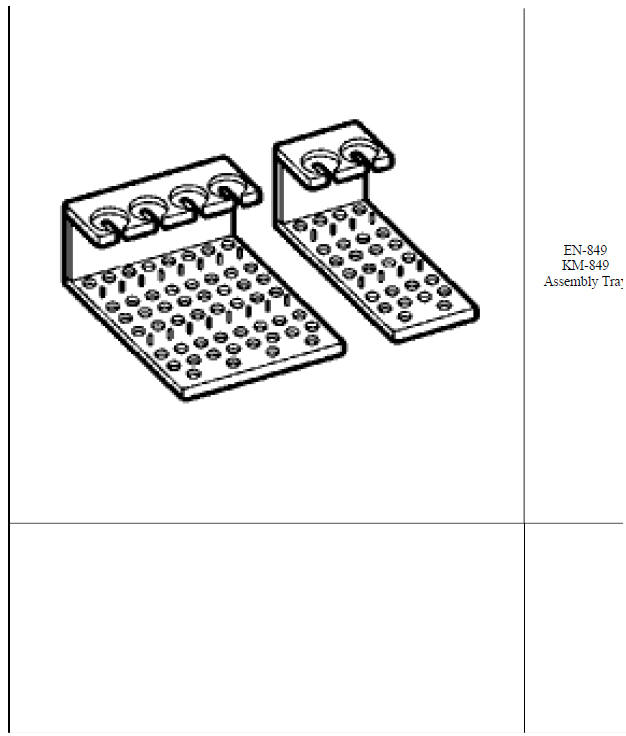

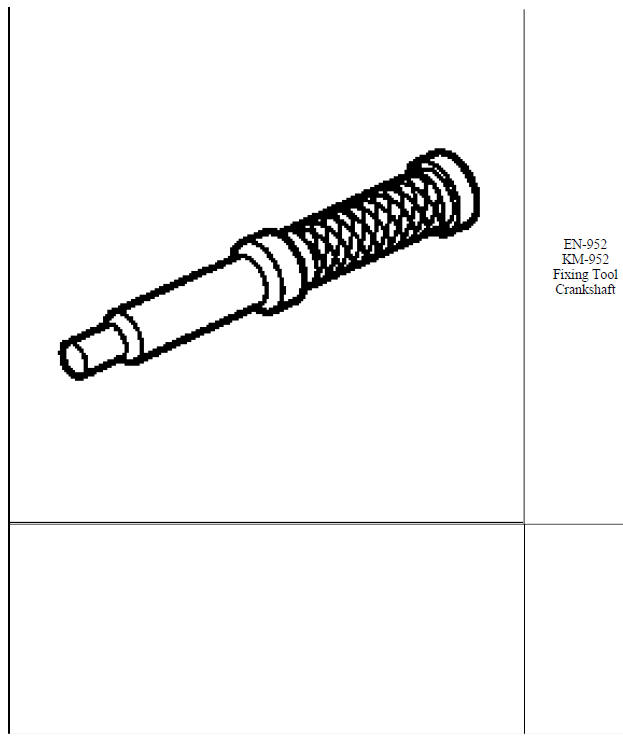

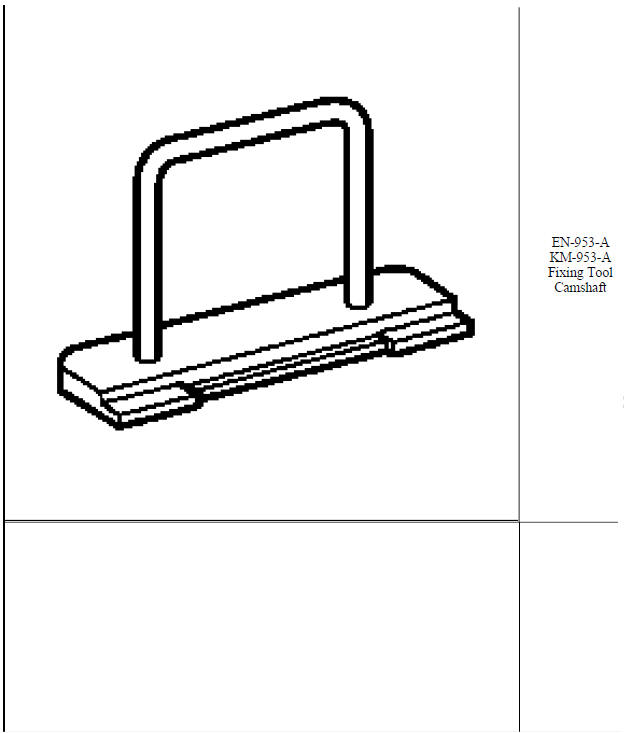

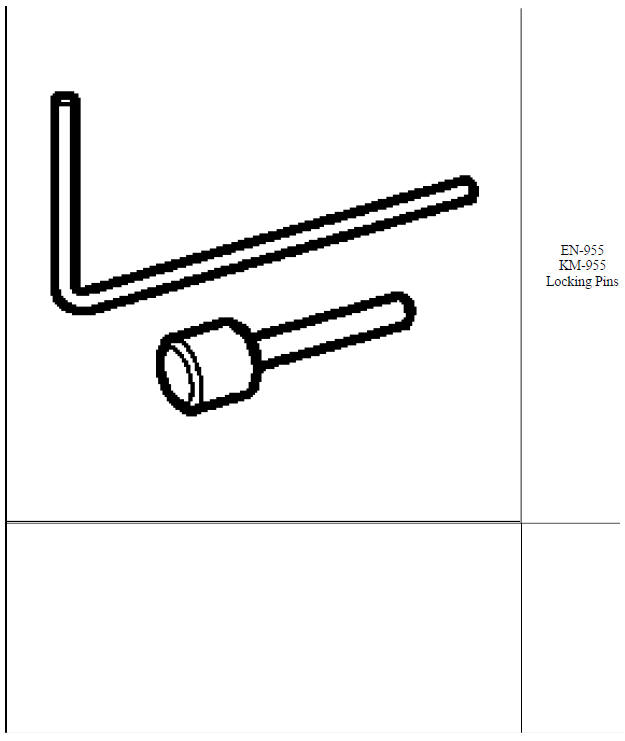

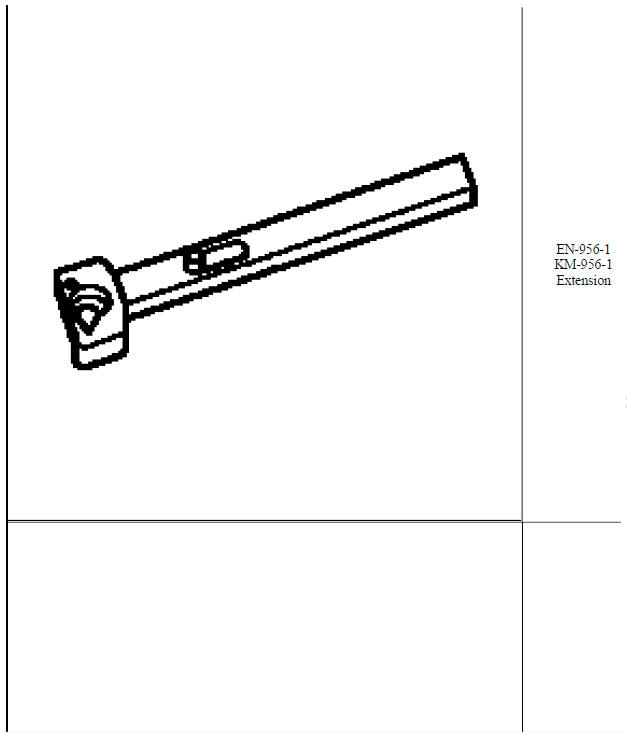

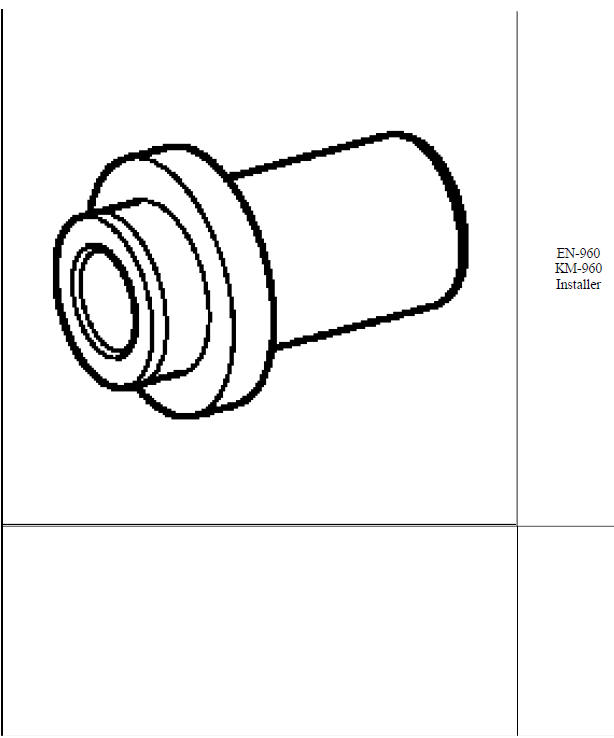

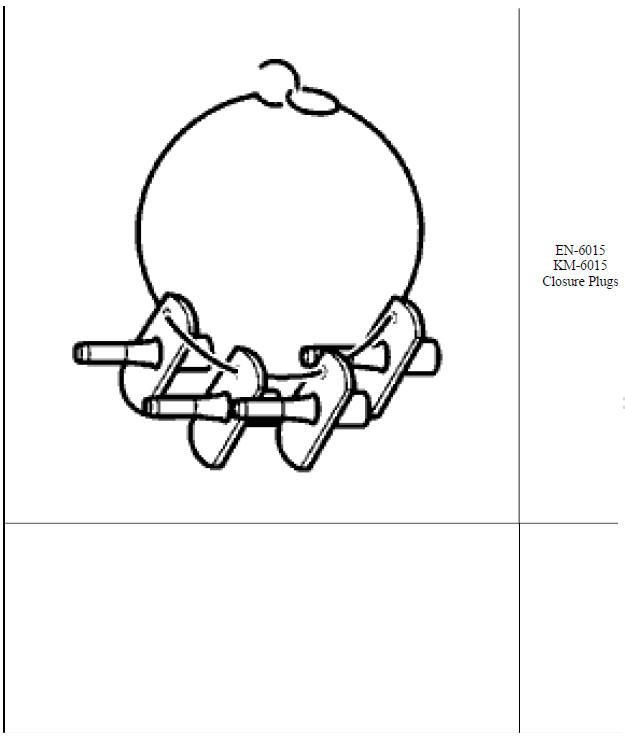

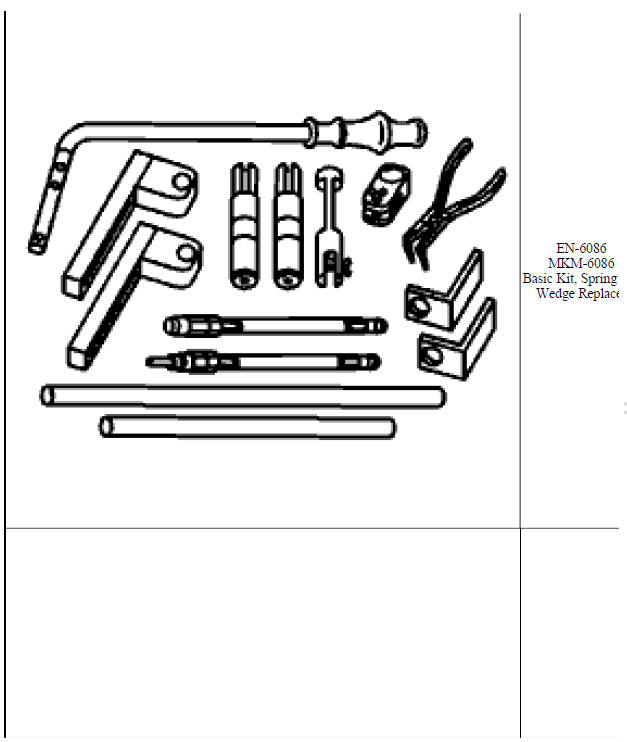

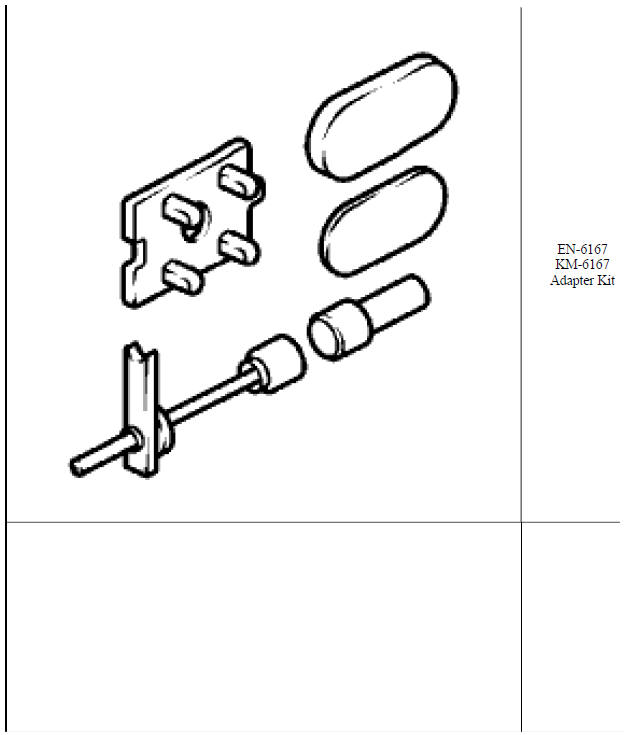

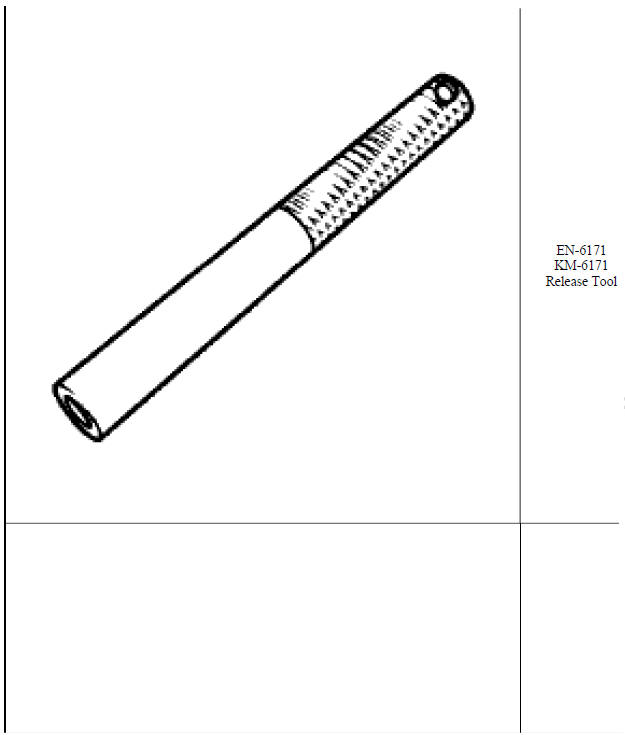

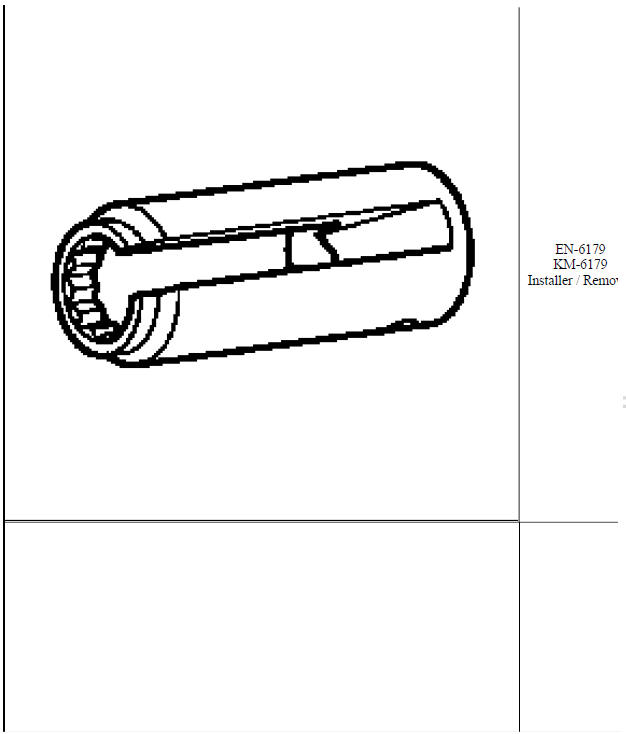

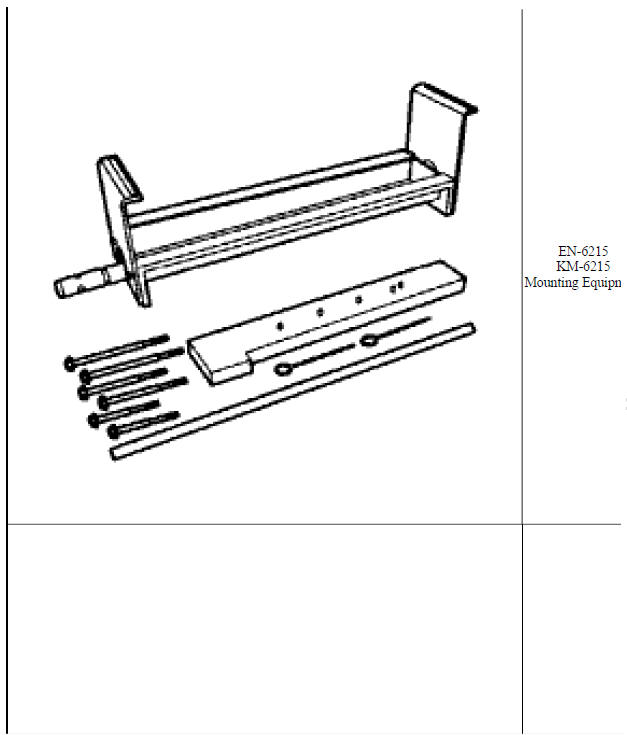

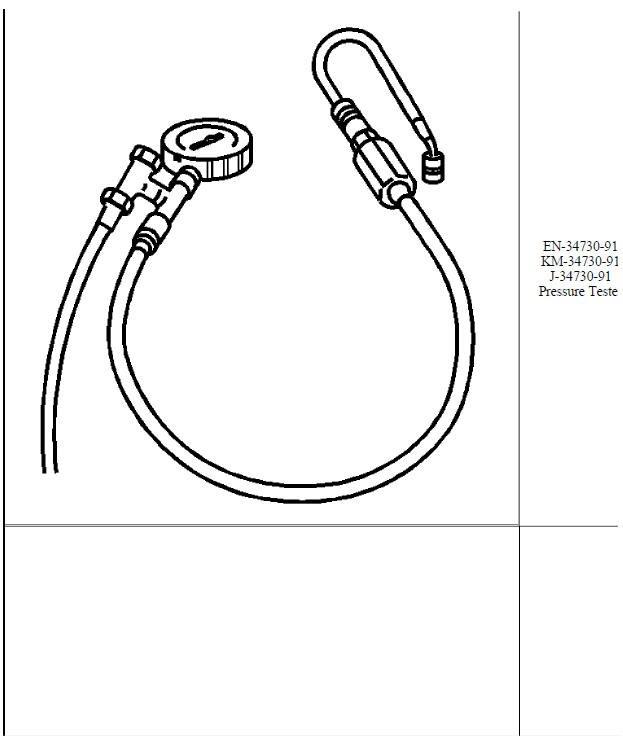

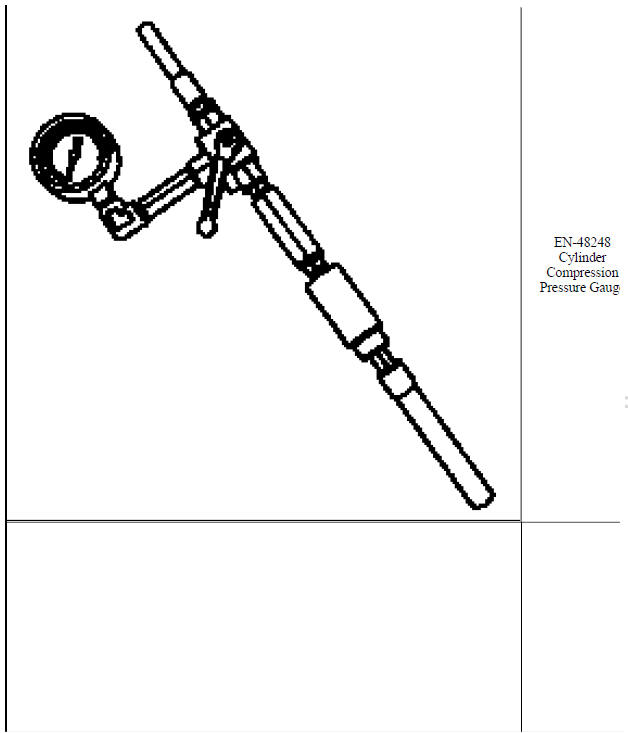

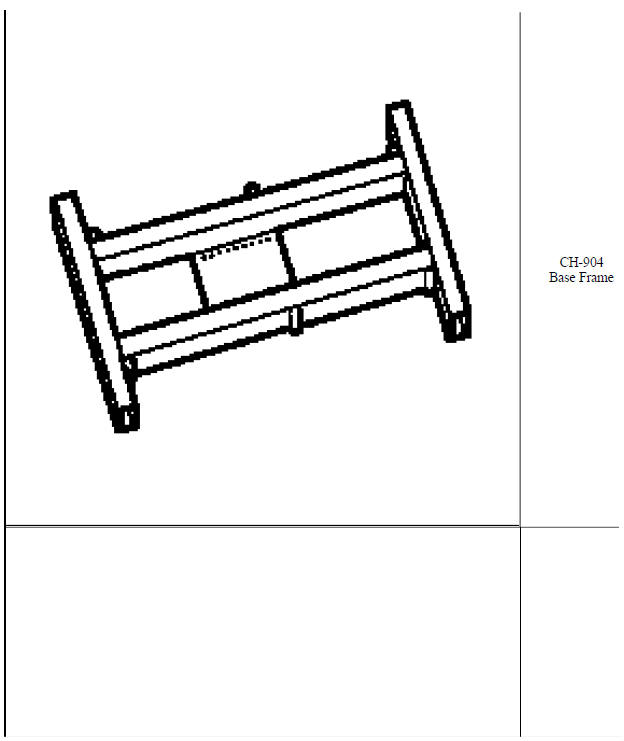

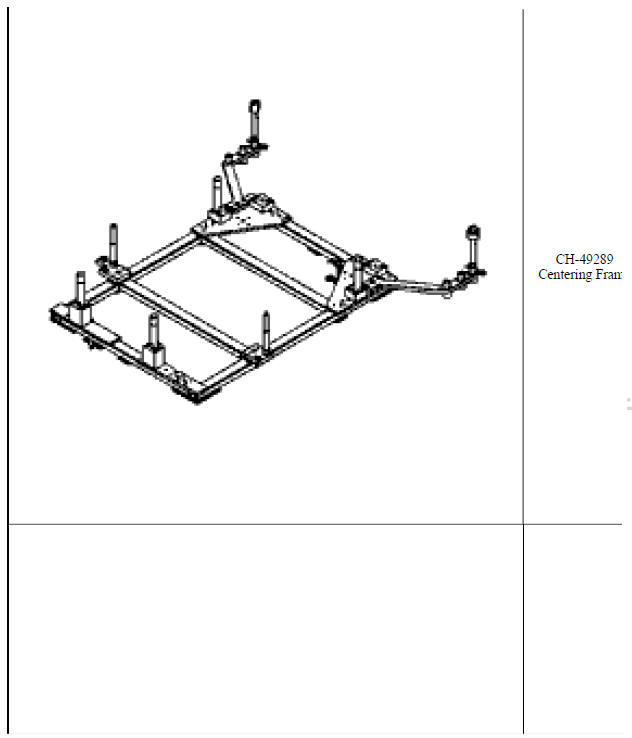

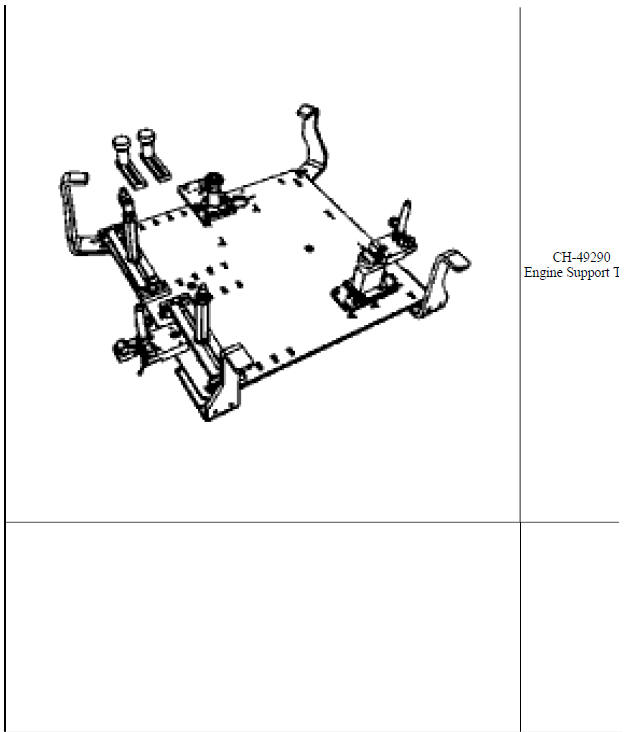

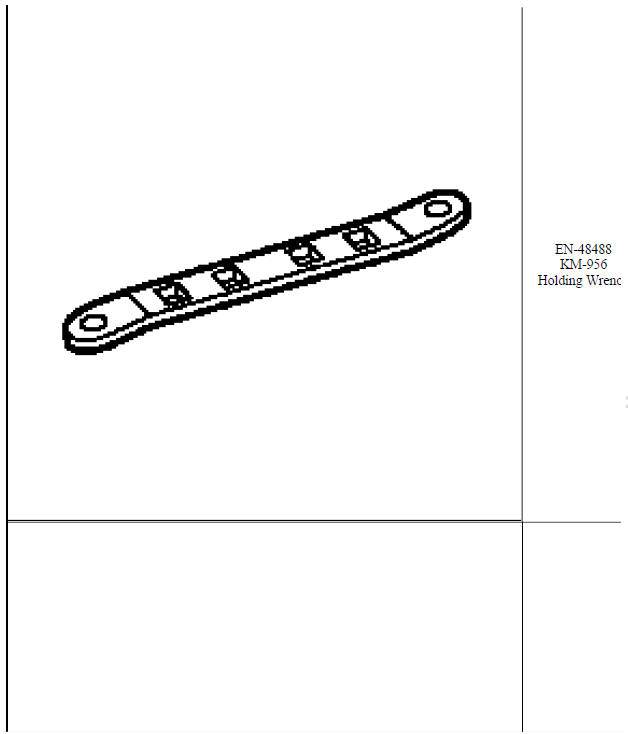

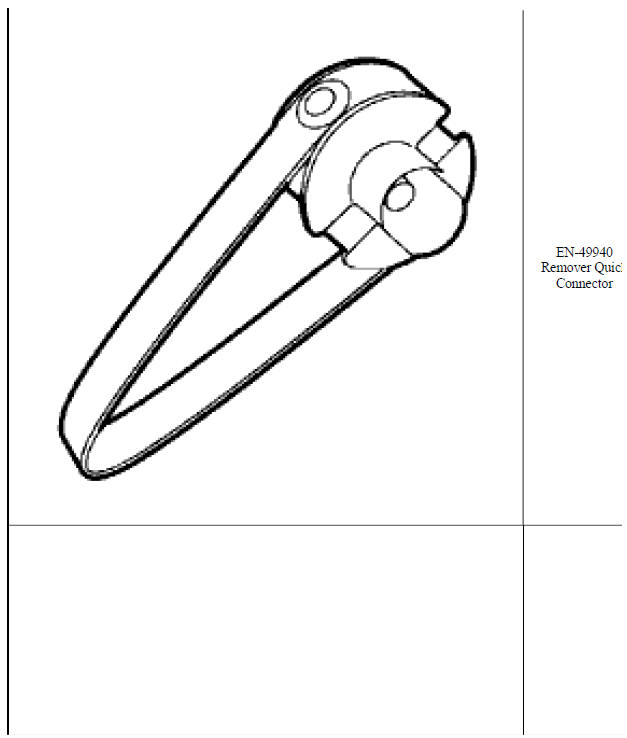

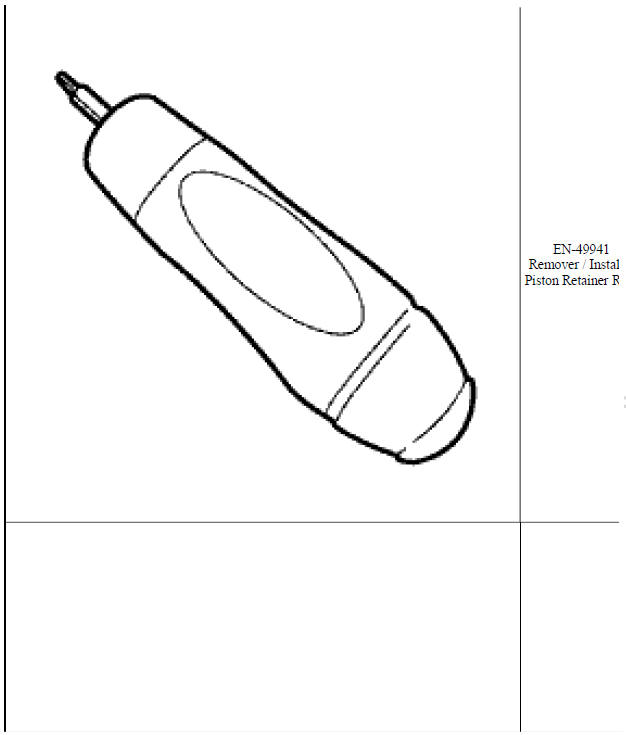

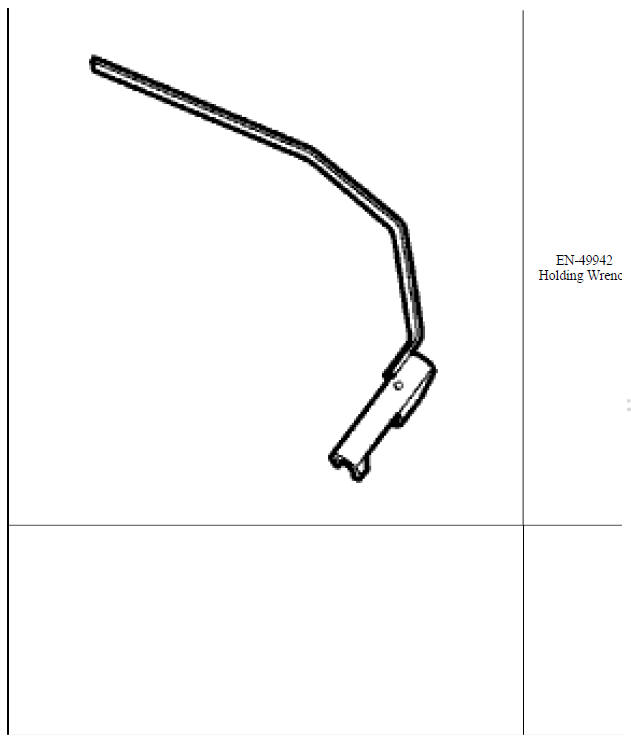

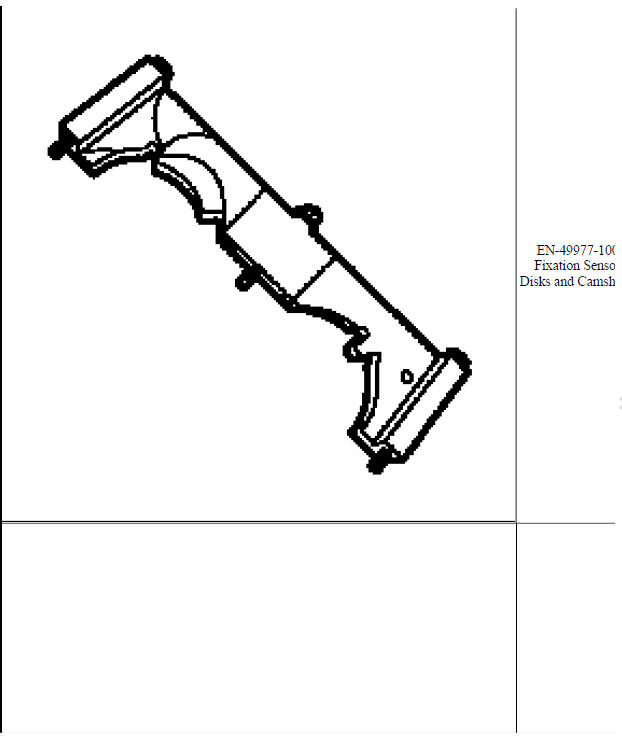

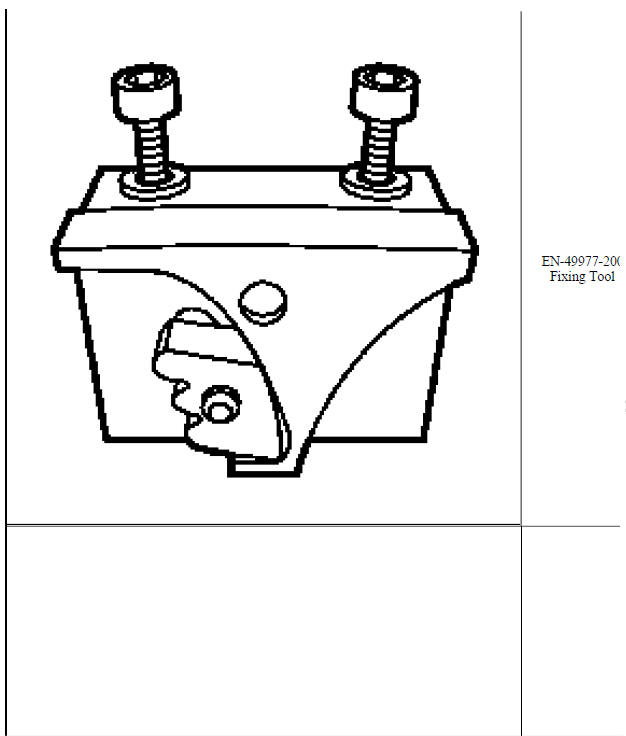

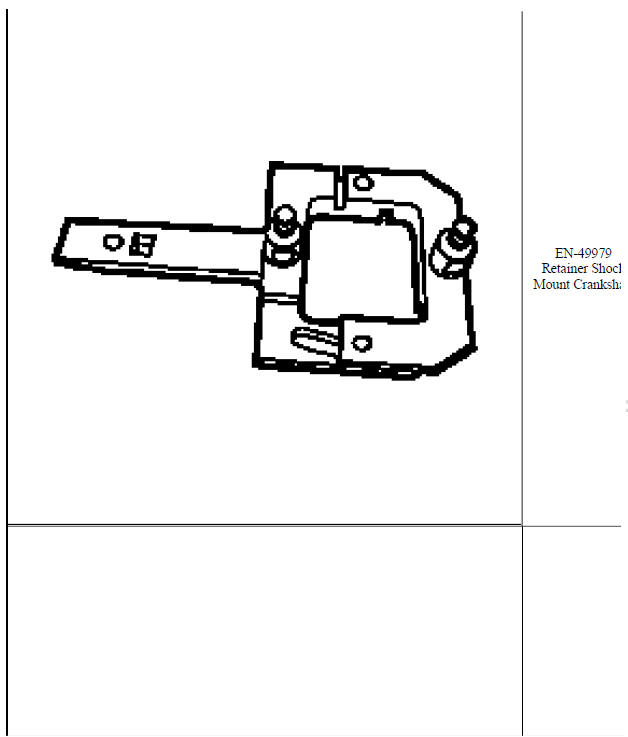

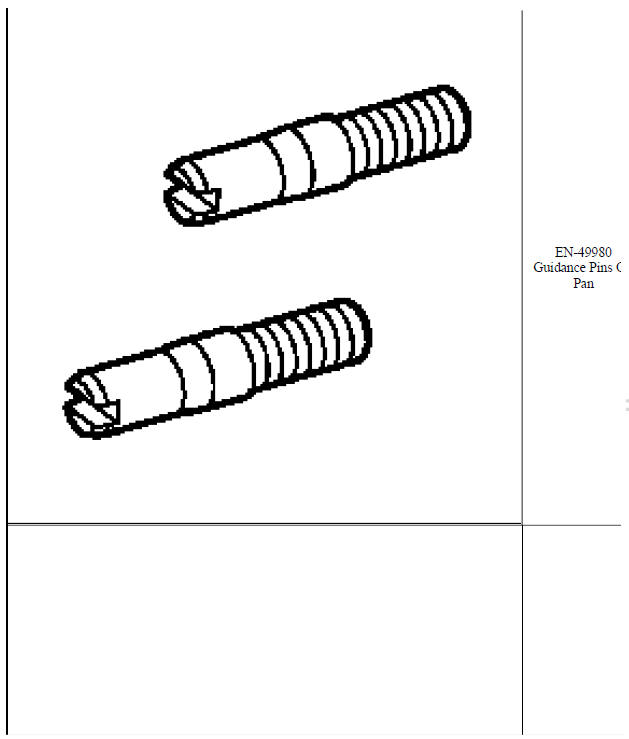

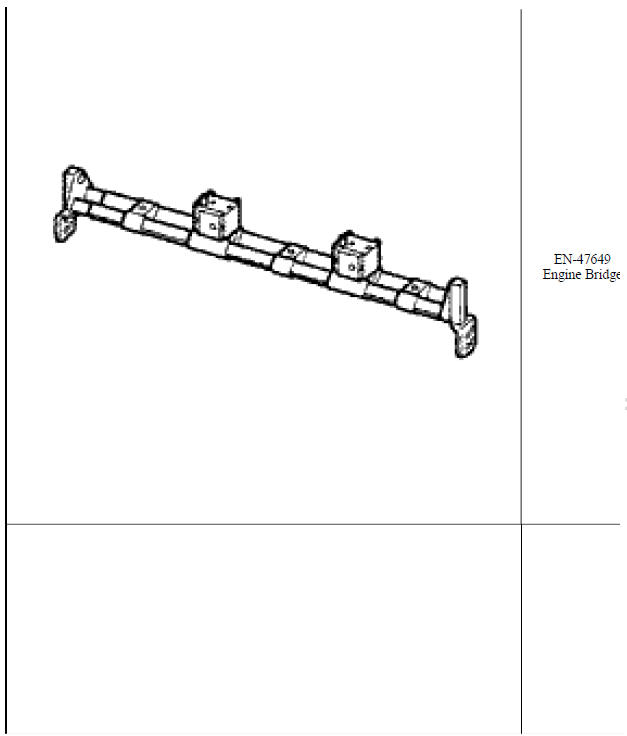

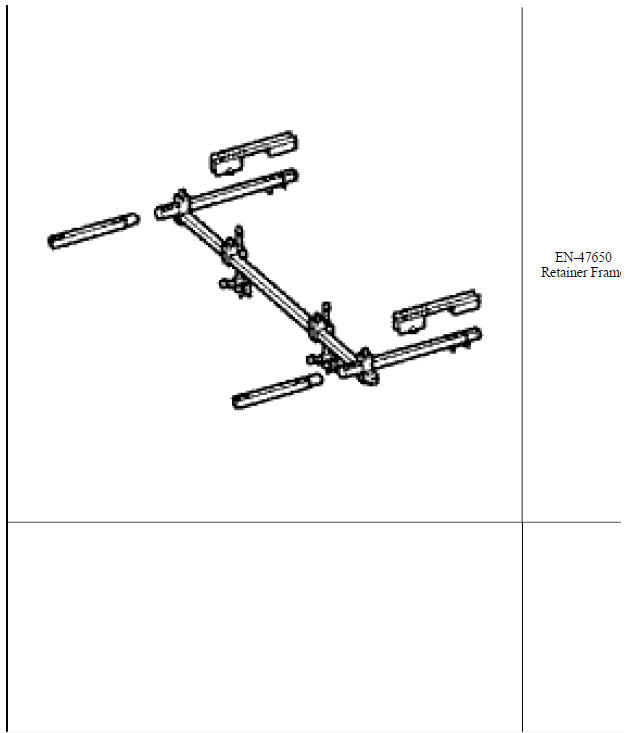

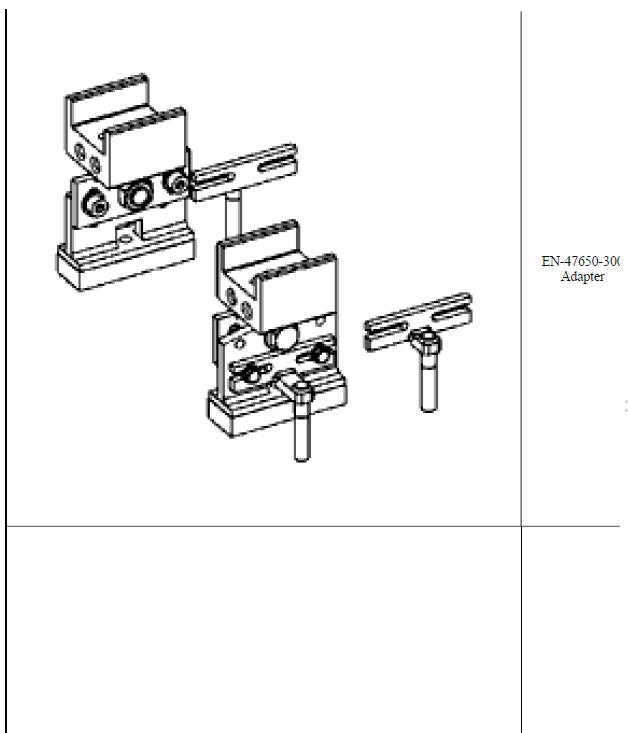

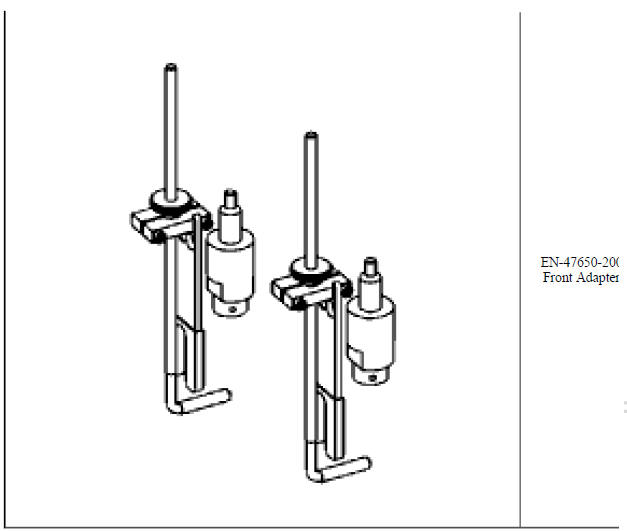

Special tools and equipment

SPECIAL TOOLS