Chevrolet Trax: DTC P2635 (Chassis control module)

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptor

DTC P2635

Fuel Pump Flow Performance

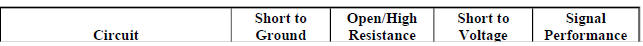

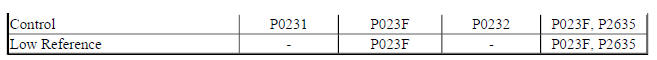

Diagnostic Fault Information

Circuit/System Description

The engine control module (ECM) supplies voltage to the chassis control module when the ECM detects that the ignition is on. The voltage from the ECM to the chassis control module remains active for 2 seconds, unless the engine is in crank or run. While this voltage is being received, the chassis control module closes the ground switch of the fuel pump and also supplies a varying voltage to the fuel tank pump module in order to maintain the desired fuel line pressure.

Conditions for Running the DTC

- DTC P018B, P018C, P018D, P0231, P0232, P023F, P064A, P1255 or P06A6 are not active.

- DTC P0641 has not failed this ignition cycle.

- Fuel pump control is enabled and the fuel pump control state is normal.

- The system voltage is greater than 11 V.

- The engine has been running for more than 30 seconds.

- Low fuel level warning not present.

Conditions for Setting the DTC

This DTC sets when the chassis control module detects a predetermined fuel pressure performance degradation between the desired fuel pressure and the current fuel pressure.

Action Taken When the DTC Sets

DTC P2635 is a Type B DTC.

Conditions for Clearing the DTC

DTC P2635 is a Type B DTC.

Diagnostic Aids

Using the Failure Records data may help locate an intermittent condition. If you cannot duplicate the DTC, the information in the Failure Records can help determine how many miles since the DTC set. The Fail Counter and Pass Counter can help determine how many ignition cycles that the diagnostic test reported a pass and/or a fail.

On vehicles equipped with a high pressure mechanical pump on Direct Fuel Injection engines, the vehicle may continue to run even though the pump in the fuel tank is not operating.

Reference Information

Schematic Reference

Engine Controls Schematics (Encore) , Engine Controls Schematics (Trax)

Connector End View Reference

WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - ENCORE WIRING SYSTEMS AND POWER MANAGEMENT - COMPONENT CONNECTOR END VIEWS - INDEX - TRAX

Description and Operation

Fuel System Description (LUJ) , Fuel System Description (LUV)

Electrical Information Reference

- Circuit Testing

- Connector Repairs

- Testing for Intermittent Conditions and Poor Connections

- Wiring Repairs

DTC Type Reference

Powertrain Diagnostic Trouble Code (DTC) Type Definitions (LUV) , Powertrain Diagnostic Trouble Code (DTC) Type Definitions (2H0)

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Testing

NOTE: Do not replace the chassis control module based on a history DTC P2635. The DTC P2635 may be stored but that does not indicate a failure of the chassis control module. Refer to Strategy Based Diagnosis for further history DTC diagnostics.

- Ignition ON.

- Verify DTCs P018B, P018C, P018D, P0231, P0232 or P023F are not set.

- If any of the DTCs are set

Refer to Diagnostic Trouble Code (DTC) List - Vehicle .

- If none of the DTCs are set

- Verify the proper fuel system pressure. Perform the fuel system pressure test, refer to Fuel System Diagnosis (LUJ), Fuel System Diagnosis (LUV).

- If the fuel system pressure test is not normal

Replace the A7 Fuel Pump and Level Sensor Assembly.

- If the fuel system pressure test is normal

- Ignition OFF and all vehicle systems OFF, disconnect the harness connector at the A7 Fuel Pump and Level Sensor Assembly. It may take up to 2 minutes for all vehicle systems to power down.

- Test for less than 10 ohms between the low reference circuit terminal 2 and ground

- If 10 ohms or greater

- Ignition OFF, disconnect the harness connector at the K38 Chassis Control Module.

- Test for less than 2 ohms in the low reference circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K38 Chassis Control Module.

- If less than 10 ohms

- Connect a test lamp between the control circuit terminal 1 and the low reference circuit terminal 2.

- Ignition ON.

- Verify the test lamp turns ON and OFF when commanding the fuel pump ON and OFF using the scan tool ECM fuel pump enable control function.

- If the test lamp is always OFF

- Ignition OFF, disconnect the harness connector at the K38 Chassis Control Module.

- Test for infinite resistance between the control circuit and ground.

- If less than infinite resistance, repair the short to ground on the circuit.

- If infinite resistance

- Test for less than 2 ohms in the control circuit end to end.

- If 2 ohms or greater, repair the open/high resistance in the circuit.

- If less than 2 ohms, replace the K38 Chassis Control Module.

- If the test lamp is always ON

- Ignition OFF, disconnect the harness connector at the K38 Chassis Control Module, ignition ON.

- Test for less than 1 V between the control circuit and ground.

- 1 V or greater, repair the short to voltage on the circuit.

- If less than 1 V, replace the K38 Chassis Control Module.

- If the test lamp turns ON and OFF

- All OK.

Repair Instructions

Perform the Diagnostic Repair Verification after completing the repair.

- Fuel Tank Fuel Pump Module Replacement (AWD) , Fuel Tank Fuel Pump Module Replacement (FWD)

- Control Module References for chassis control module replacement, programming and setup

SYMPTOMS - ENGINE CONTROLS

Diagnostic Instructions

- Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

- Review Strategy Based Diagnosis for an overview of the diagnostic approach.

- Diagnostic Procedure Instructions provides an overview of each diagnostic category.

Symptoms Description

Symptoms cover conditions that are not covered by DTCs. Certain conditions can cause multiple symptoms.

These conditions are listed together under Symptoms Testing. Conditions that may only cause specific symptoms are listed separately under additional symptoms testing. Perform the symptoms testing before using the additional symptoms testing.

Symptoms Definition

Backfire

Fuel ignites in the intake manifold or in the exhaust system, making a loud popping noise.

Cuts Out, Misses

A steady pulsation or jerking that follows engine speed, which is usually more pronounced as the engine load increases. This condition is not normally felt above 1 500 RPM or 48 km/h (30 MPH). The exhaust has a steady spitting sound at idle or at low speed.

Detonation/Spark Knock

A mild to severe ping which usually gets worse while under acceleration. The engine makes sharp metallic knocks that change with throttle opening.

Dieseling, Run-On

Fuel ignites in the intake manifold or in the exhaust system, making a loud popping noise.

Engine Control Module (ECM) Commanded Reduced Engine Power

The ECM illuminates the Reduced Engine Power lamp and will limit engine power under potential engine/vehicle damaging or emissions related conditions. A DTC may not be set.

Hard Start

Engine cranks OK, but does not start for a long time. The vehicle does eventually run, or may start but immediately stalls.

Hesitation, Sag, Stumble

Momentary lack of response as the accelerator is pushed down. This condition can occur at any vehicle speed. This condition is usually more pronounced when first trying to make the vehicle move, as from a stop. This condition may cause the engine to stall in severe conditions.

Lack of Power, Sluggishness, or Sponginess

The engine delivers less than expected power. Little or no increase in speed when the accelerator pedal is pushed down part way.

Poor Fuel Economy

Fuel economy, as measured by an actual road test, is noticeably lower than expected. Also, the fuel economy is noticeably lower than it was on this vehicle at one time, as previously shown by an actual road test.

Rough, Unstable, or Incorrect Idle and Stalling

The engine runs unevenly at idle. If severe, the engine or the vehicle may shake. Engine idle may vary in speed. Either condition may be severe enough to stall the engine.

Surges/Chuggles

Engine power variation under steady throttle or cruise. Feels like the vehicle speeds up and slows down with no change in the accelerator pedal position.

Symptoms Verification

Before using the Symptom tables, perform the following inspections:

- Verify that the malfunction indicator lamp (MIL) is operating correctly. Use the scan tool to command the lamp ON and OFF.

- Verify that there are no DTCs that are stored.

- Verify that the scan tool data is within a normal operating range. Refer to Control Module References for scan tool information.

- Verify the customer concern.

- Perform the Visual/Physical Inspection in this section. The visual/physical inspection is extremely important, and can lead to correcting a condition without additional testing. It may also help reveal the cause of an intermittent condition.

- Verify that there are no bulletins for the current symptom.

- Verify that the vehicle tires are correctly inflated and meet original equipment specifications.

Identifying Intermittent Conditions

Many intermittent conditions occur with harness or connector movement due to engine torque, rough pavement, vibration or physical movements of a component. Refer to the following for a list of issues that may cause an intermittent condition:

- Moisture and water intrusion in connectors, terminals, and components

- Incomplete connector mating

- Poor terminal contact

- High circuit or component resistance-High resistance can include any resistance, regardless of the amount, which can interrupt the operation of the component.

- Harness that is too short or tight

- Wire insulation that is chaffed or cut

- High or low ambient temperature

- High or low engine coolant temperatures

- High underhood temperatures

- Heat build up in component or circuit due to circuit resistance, poor terminal contact, or high electrical load

- High or low system voltage

- High vehicle load conditions

- Rough road surfaces

- Electro-magnetic interference (EMI)/circuit interference f

- Incorrect installation of aftermarket, add on accessories

Visual/Physical Check

- Verify that the control module grounds are clean, tight, and correctly located.

- Verify that the vacuum hoses are not split or kinked, and are properly connected, as shown on the Vehicle Emission Control Information label.

- Verify that the air filter is clean and free from restrictions.

- Verify that there is no water intrusion in connectors terminals and components.

- Inspect the air intake ducts for the following conditions:

- Collapsed

- Damaged areas

- Looseness

- Incorrect installation

- Leaking

- Inspect for air leaks at the throttle body mounting area, the mass air flow (MAF) sensor and intake manifold sealing surfaces.

- Inspect the wiring harness for the following conditions:

- Poor connections

- Pinches

- Cuts

- Inspect for loose, damaged, unseated, or missing sensors/components.

- Inspect the terminals for corrosion and correct contact.

Symptoms Testing

Backfire, Cuts Out/Misses, Detonation/Spark Knock, Dieseling/Run-On, Engine Control Module (ECM) Commanded Reduced Engine Power, Hard Start, Hesitation/Sag/Stumble, Lack of Power/Sluggishness/Sponginess, Poor Fuel Economy, Rough, Unstable, or Incorrect Idle and Stalling, or Surges/Chuggles

- Test for the following conditions:

- Incorrectly operating fuel system. Test for the following:

- Correct fuel pressure - Refer to Fuel System Diagnosis (LUJ), Fuel System Diagnosis (LUV).

- Fuel injectors that are leaking or improperly operating - Refer to Fuel Injector Diagnosis.

- Contaminated or a poor fuel quality condition - Refer to Alcohol/Contaminants-in-Fuel Diagnosis.

- Incorrectly operating ignition system. Test for the following:

- Spark plugs with incorrect heat range or an abnormal condition - Refer to Spark Plug Inspection , and Ignition System Specifications .

- Coolant or oil fouled spark plugs - Refer to Oil Consumption Diagnosis , and Loss of Coolant .

- Secondary ignition system susceptible to moisture. Engine running, wet down the secondary ignition system with water from a spray bottle to help locate damaged or deteriorated components. Look/listen for arcing or misfiring as the water is applied.

- Weak spark using the EL 26792 HEI spark tester. For equivalent regional tools, refer to Special Tools (Diagnostic Tools) , . Refer to Electronic Ignition System Diagnosis.

- Incorrectly operating turbocharger system. Inspect the turbocharger charge air cooler system for leaks and refer to:

- Turbocharger Cleaning and Inspection

- Turbocharger System Description

- Incorrectly operating transmission torque converter clutch (TCC) - The scan tool should indicate an engine speed drop when the TCC is commanded ON.

- Incorrectly operating A/C compressor

- Items that can cause an engine to run lean or rich - Refer to DTC P0171 or P0172 .

- Incorrectly installed Mass Air Flow (MAF)/Intake Air Temperature (IAT) Sensor.

- Incorrect crankshaft position sensor resistance - The crankshaft position sensor resistance may be out of range after a hot soak. The resistance should be between 700 - 1200 ohms.

- Split or kinked vacuum hoses - Verify that the routing and connections are as shown on the vehicle emission control information label.

- Excessive knock sensor system spark retard activity or faulty operation - Refer to Knock Sensor Replacement , DTC P0325, P0327, or P0328, and DTC P0324, P0326, or P06B6 .

- Incorrect fuel octane switch setting, if equipped - Verify the fuel octane switch is set to the proper fuel octane rating for the fuel being used in the vehicle.

- Electromagnetic interference on the reference circuit, which can cause a misfire condition. You can usually detect electromagnetic interference with a scan tool by monitoring the engine speed parameter. A sudden increase in the engine speed parameter with little change in actual engine speed indicates that electromagnetic interference is present. Inspect the high voltage components near the ignition control circuit if a condition exists.

- A leaking or restricted positive crankcase ventilation system.

- A stuck open Evaporative Emission (EVAP) Canister Purge Solenoid Valve.

- A faulty exhaust system. Inspect the components for the following:

- Physical damage or possible internal failure

- Restricted 3-way catalytic converters

- Incorrectly operating engine cooling system. Inspect for the following:

- A thermostat with incorrect heat range. Refer to Thermostat Diagnosis .

- Incorrect engine coolant level - Refer to Cooling System Draining and Filling .

- Incorrectly operating engine coolant thermostat heater. Refer to DTC P0597-P0599 (2H0 or LUJ)

- An engine mechanical condition. Verify the conditions listed below do not exist:

- Excessive oil in the combustion chamber or leaking valve seals

- Incorrect cylinder compression

- Sticking or leaking valves

- Worn camshaft lobes

- Incorrect valve timing

- Broken valve springs

- Excessive carbon buildup in the combustion chambers. Clean the chambers with Top Engine Cleaner, if necessary. Follow the instructions on the can.

- Incorrect engine parts

For additional information, refer to Symptoms - Engine Mechanical .

- If the above conditions do not address the symptom, refer to the additional symptoms tests.

Additional Symptoms Tests

Detonation/Spark Knock

- Test the engine for an overheating condition. Refer to Symptoms - Engine Cooling .

- Inspect for excessive carbon buildup in the combustion chambers. Clean the chambers with Top Engine Cleaner, if necessary. Follow the instructions on the can.

- If there are no engine mechanical faults, fill the fuel tank with a known high quality fuel that meets the vehicle minimum octane requirements.

Engine Control Module (ECM) Commanded Reduced Engine Power

Under certain conditions the engine control module may limit engine power by reducing engine torque and, for some vehicles, fuel pressure as well. For most, but not all of the conditions, the engine control module will illuminate the reduced engine power lamp on the instrument cluster. If equipped with the driver information center feature, a reduced engine power message may be displayed as well. A DTC may not be set.

A repair may not be necessary. Observe the scan tool Reduced Engine Power History parameter or refer to K20 Engine Control Module: Scan Tool Information (LUV or 2H0) to determine the reason for the reduced engine power event.

Verify or inspect for the following:

- Vehicle being operated at sustained high engine speeds, or, towing heavy loads up an incline for an extended period of time, which may cause the engine oil or coolant to overheat. Inspect the airflow passageways in front of the engine for obstructions and clear away any debris or foreign material that is found. If no obstructions are found, review approved driving habits with the customer. The customer may need to operate the vehicle at a higher engine speed to improve cooling system performance, or, at a slower engine speed to reduce engine load.

- A cooling fan condition which may cause the engine coolant to overheat. Refer to Cooling Fan Description and Operation (LUJ or LUV) , Cooling Fan Description and Operation (2H0), and Cooling System Description and Operation to verify correct operation of the cooling fan.

- If the vehicle is equipped with the OnStar feature, reduced engine power may be due to OnStar remote command. Verify the vehicle is not in the OnStar initiated Stolen Vehicle Slowdown mode.

- A high pressure fuel system condition. Refer to Fuel System Diagnosis (LUJ), Fuel System Diagnosis (LUV), and Fuel System Description (LUJ) , Fuel System Description (LUV) to verify high pressure fuel system operation.

- Maximum recommended engine oil life exceeded. Refer to the Owners Manual for scheduled maintenance recommendations.

- Intake air temperature out of range too high. Engine running, observe

the scan tool IAT Sensor parameter.

The readings should be between -40ºC and +149ºC (-40ºF and +300ºF). Refer to DTC P0112, P0113, or P0114 for additional information.

- Fuel temperature out of range too high.

- Turbocharger boost pressure out of range. Refer to DTC P0234 or P0299 .

- If equipped with manual transmission, excessively hot manual transmission fluid. Under severe operating conditions, the fluid may become overheated, which may result in ECM commanded reduced engine power. Allow the transmission and fluid to cool down. Review the maintenance recommendation in the owners manual to determine if the transmission fluid is due to be serviced.

- If equipped with automatic transmission, an incorrect learned brake pedal position (BPP) sensor. Verify the following actions have not occurred:

- An engine control module (ECM) has been replaced

- A BPP sensor has been replaced

- A BPP sensor is misaligned or incorrectly installed

If any of the above actions have occurred, the Brake Pedal Position Sensor Learn procedure must be performed.

Fuel Odor

- Inspect for a saturated EVAP canister - Refer to Evaporative Emission Control System Description .

- Inspect for leaking, damaged, or deteriorated fuel lines.

- Inspect for a condition with the internal components of the fuel tank assembly-Refer to Fuel System Description (LUJ) , Fuel System Description (LUV) .

Hard Start

- Observe the scan tool Throttle Body Idle Airflow Compensation parameter. A value greater than 90% may indicate an excessive accumulation of deposits in the throttle bore. Inspect the throttle body and bore and clean, if necessary. Refer to Throttle Body Inspection and Cleaning .

- Test the engine coolant temperature (ECT) sensor. Compare the ECT sensor value to the intake air temperature (IAT) sensor value on a cold engine. The ECT and IAT sensor values should be within approximately 3ºC (5ºF). If the ECT sensor is out of range with the IAT sensor, test the resistance of the ECT sensor. Refer to Temperature Versus Resistance for resistance specifications. Replace the ECT sensor if the resistance is not within specification. If the sensor is within the specification, test the ECT circuits for a high resistance.

- Test the fuel pump operation. The fuel pump should turn ON for 2 s when the ignition is turned ON.

Hesitation, Sag, Stumble

- Test the fuel pressure. Refer to Fuel System Diagnosis (LUJ), Fuel System Diagnosis (LUV).

- Test the manifold absolute pressure (MAP) sensor. Refer to DTC P0106 .

- Test the generator. Refer to Symptoms - Engine Electrical . Repair the charging system if the generator output voltage is less than 9 V or more than 16 V.

NOTE: The following actions may need to be repeated in order to verify an intermittent intake or exhaust camshaft actuator condition.

- Engine warm and idling, verify the correct operation of the camshaft actuator system. Command the intake and exhaust camshaft actuators from 0 degrees to 20 degrees and back to zero while observing the scan tool Intake Camshaft Position Variance and Exhaust Camshaft Position Variance parameters. Each parameter should be less than 2 degrees in each of the commanded states.

- If any of the parameters is greater than 2 degrees, inspect the suspect camshaft actuator and camshaft actuator solenoid valve and valve bore for contamination, obstruction, and damage. Refer to Camshaft Actuator System Description , and Camshaft Position Actuator Solenoid Valve Replacement .

Lack of Power, Sluggishness, or Sponginess

- Inspect the engine electrical system for correct operation. Refer to Symptoms - Engine Electrical .

- Verify that each injector harness is connected to the correct injector.

- Inspect the mass air flow (MAF) sensor for obstruction, contamination, and damage. Refer to Mass Airflow Sensor Replacement .

NOTE: The following actions may need to be repeated in order to verify an intermittent intake or exhaust camshaft actuator condition.

- Engine warm and idling, verify the correct operation of the camshaft actuator system. Command the intake and exhaust camshaft actuators from 0 degrees to 20 degrees and back to zero while observing the scan tool Intake Camshaft Position Variance and Exhaust Camshaft Position Variance parameters. Each parameter should be less than 2 degrees in each of the commanded states.

- If any of the parameters is greater than 2 degrees, inspect the suspect camshaft actuator and camshaft actuator solenoid valve and valve bore for contamination, obstruction, and damage. Refer to Camshaft Actuator System Description , and Camshaft Position Actuator Solenoid Valve Replacement

- Test the turbocharger system for air leaks. Engine running, use a smoke generating device or a solution of dish soap and water in a spray bottle to pinpoint any air leaks

- Verify that the conditions listed below do not exist with the turbocharger assembly. Refer to Turbocharger Cleaning and Inspection .

- Worn or damaged wastegate pivot pin.

- Cracked, damaged, or worn turbine blades.

- Restricted wastegate, turbine ports or passages.

- Contamination with foreign material.

- Verify the correct operation of the turbocharger system. Refer to DTC P0234 or P0299

Poor Fuel Economy

- Inspect for heavy loads being carried or towed

- Inspect for acceleration rate too much or too often

- Inspect for incorrect operation of the speedometer.

- Observe the scan tool Throttle Body Idle Airflow Compensation parameter. A value greater than 90% may indicate an excessive accumulation of deposits in the throttle bore. Inspect the throttle body and bore and clean, if necessary. Refer to Throttle Body Inspection and Cleaning .

- Inspect the brake system for brake drag.

Rough, Unstable, or Incorrect Idle and Stalling

- Inspect the engine mounts Engine Mount Replacement - Right Side .

- Observe the scan tool Throttle Body Idle Airflow Compensation parameter. A value greater than 90% may indicate an excessive accumulation of deposits in the throttle bore. Inspect the throttle body and bore and clean, if necessary. Refer to Throttle Body Inspection and Cleaning .

- An excessively high idle may be due to the floor mat interfering with the accelerator pedal. With this condition present, it may not be possible to shift the transmission into gear. Inspect the accelerator pedal for binding and verify that the floor mat is not interfering with the aceclerator pedal movement.

Surges/Chuggles

- Inspect for slow responding heated oxygen sensors (HO2S). The HO2S should respond quickly to a change in throttle position. If the HO2S do not respond to different throttle positions, inspect for contamination from fuel, silicon, or the incorrect use of room temperature vulcanizing sealant. The sensors may have a white powdery coating and result in a high, but false, signal voltage, which gives a rich exhaust indication. The ECM reduces the amount of fuel delivered to the engine, causing a driveability condition.

- Verify that each injector harness is connected to the correct injector.